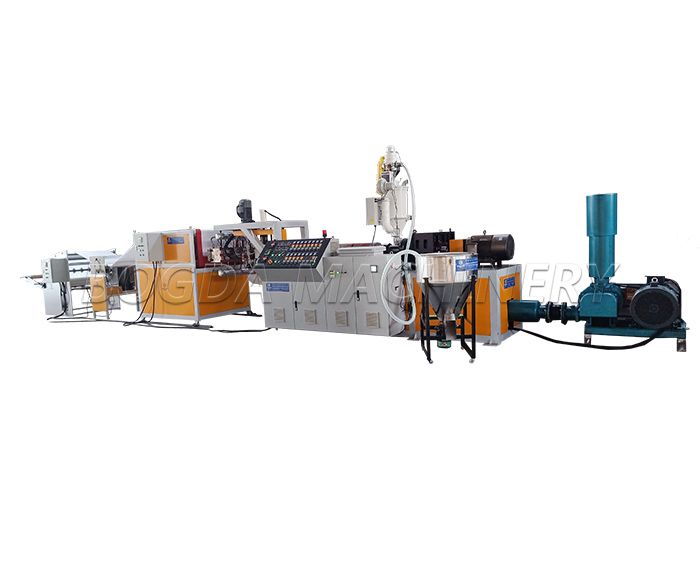

Max. width:1600mm,Production speed:5-50m/min,Machine power:300kw,Oven temperature:45-100℃

| 最大宽度Max. width | 生产速度 Production speed | 整机功率 Machine power | 烘箱温度 Oven temperature |

| 1600mm | 5-50m/min | 300kw | 45-100℃ |

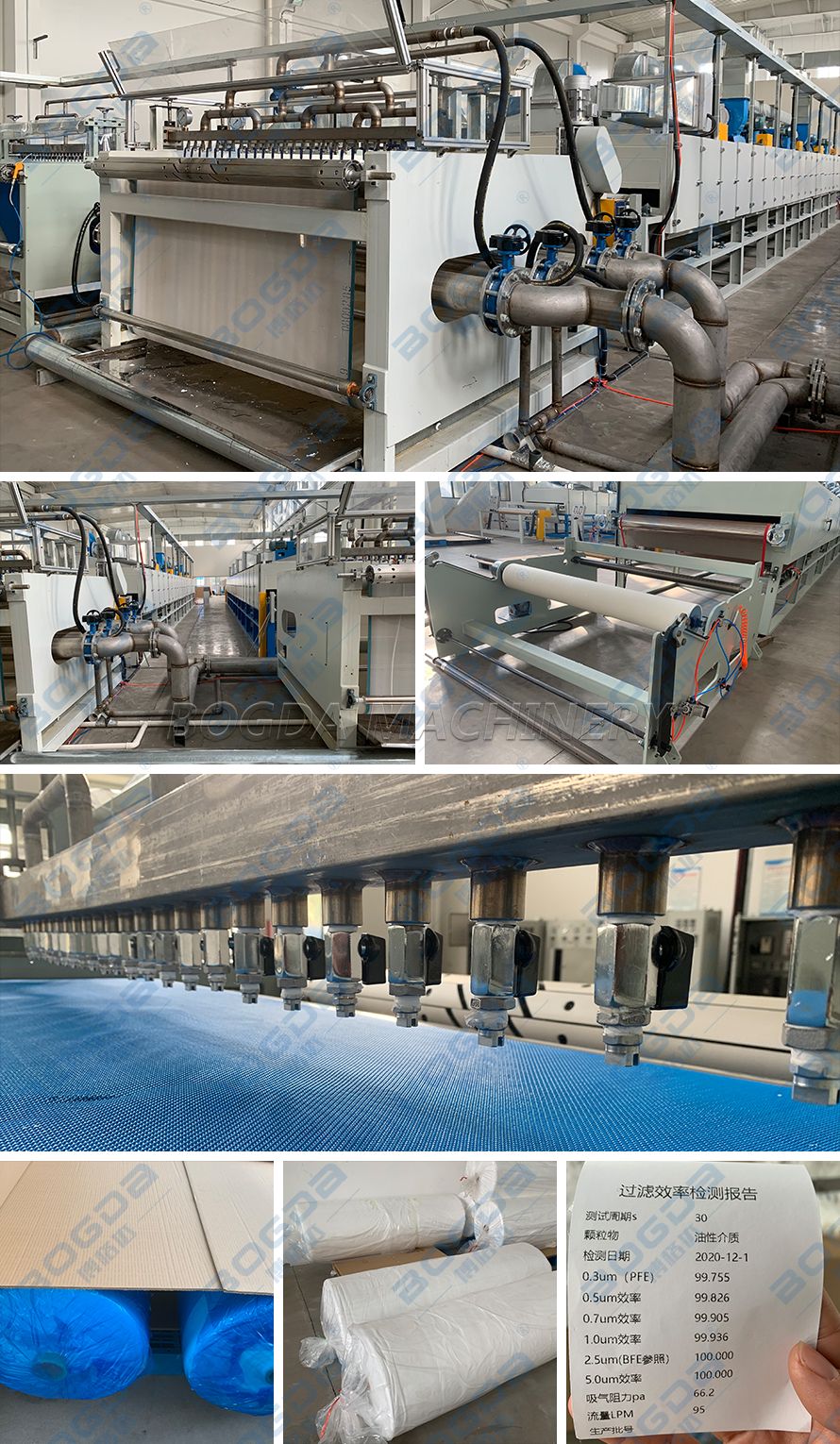

The specific production process is as follows:

Step 1: Choose polypropylene granules as raw materials

Polypropylene granules raw material conveying to extrusion machine, extruder extrusion raw material through the

die head of spinneret, air compressor produced by the airflow and the jet direction of raw material, will have a air

compressor, air heater for heating, receive the die spinneret roller spewing raw material receiving, formation of

non-woven fabric after receiving roller.

Step 2: Preparation of pure water

Select tap water as the water source, sand and gravel tank filtration and activated carbon tank filtration of the water

source, add antiosmosis agent and hydrochloric acid to the filtered water source, reverse osmosis membrane

secondary filtration of the water source, add alkaline industrial reagent to the filtered water source, complete the

preparation of pure water.

Step 3: Electret process

Deliver the prepared pure water to the fan nozzle through the high-pressure water pump, and the fan nozzle

conduct spuning through the molten spray cloth; Through the friction of pure water and non-woven cloth, electric

charge is generated to complete the spunlaced electret.

Step 4: Drying process

The non-woven cloth after spuning pole is transported to the drying room through the transfer mechanism, and

the drying is carried out by means of electric heating and hot air shower. Receive through receiving roller after drying.

Step 1: Film packaging for Bfe 99% Filter Grade 1600mm PP Melt Blown Nonwoven Fabric Making Machine Equipment

* BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile, pipe, sheet extrusion equipment,

waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar

with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

* BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order.

Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials

to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

* Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Hanger-type 1600mm Europen Standard FFP2 FFP3 KF4 Face Masks Meltblown Fabric Making Machine With Spunlace/Water Electret Treatment Equipment

Hanger-type 1600mm Europen Standard FFP2 FFP3 KF4 Face Masks Meltblown Fabric Making Machine With Spunlace/Water Electret Treatment Equipment  800mm Horizonal Type PP Melt Blown Fabric Manufacturing Plant

800mm Horizonal Type PP Melt Blown Fabric Manufacturing Plant  1.6m Water Electret Electrostatic Equipment PP Melt Blown Nonwovens Fabric Machine Manufacturer

1.6m Water Electret Electrostatic Equipment PP Melt Blown Nonwovens Fabric Machine Manufacturer  BOGDA 1600mm PP Melt Blown Nonwovens Fabric Machine Manufacturing Factory

BOGDA 1600mm PP Melt Blown Nonwovens Fabric Machine Manufacturing Factory Copyright © Bogda Machinery Group All Rights Reserved | Sitemap | Powered by