1. Hot stamping PVC panle manufacture machine is suitable for the production of PVC and WPC as raw material products. 2. By replacing the mould, the same production line can be used to produce PVC/WPC ceiling panel,wall panel,U-Clip,flooring,decorative lines etc.

Product Description

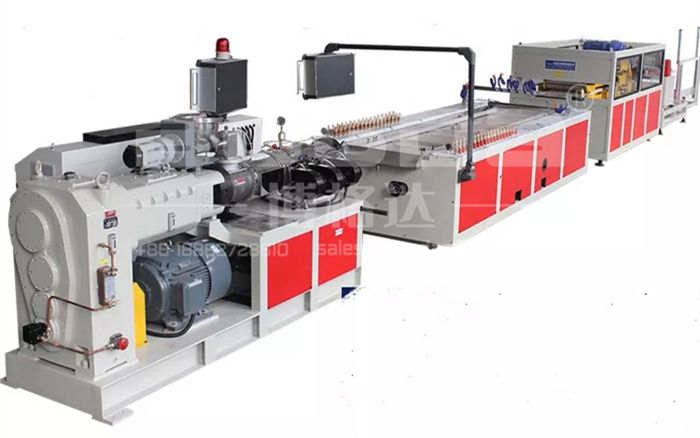

PVC ceiling panel Hot stamping Machine

1. Hot stamping PVC panle manufacture machine is suitable for the production of PVC and WPC as raw material products.

2. By replacing the mould, the same production line can be used to produce PVC/WPC ceiling panel,wall panel,U-Clip,flooring,decorative lines etc.

3.Depending on the different products,this production line can be configured with on-line hot printing and off-line lamination.

| Effective thermo printing width | 600mm | Laminating speed | 1~10m/min |

| Thickness of sheet | 2~40mm | Driver power | 0.75kw |

| Heating power | 6kw | Total power | 7kw |

Conveying unit

1. The frame of equipment adopts channel steel to weld;

2. The conveying roller and press roller are made of seamless steel pipe wrapped with NBR; Q235 steel made guide board of press roller is controlled by air cylinder of diameter 63;

3. It adopts NBR wheels as baffle plate to control the location of board;

4. It adopts 45# steel to make the drive chain-wheels, bevel gears and drive axes.

5. The drive motor is cycloid decelerating motor (power is 1.5kw) and the working speed is controlled by Timing Motor Drive.

Thermo-printing on the plane unit

1. It adopts rubber roller to level up the thermo-printing film;

2. It adopts Q235 steel to make thermo-printing wall board;

3. The medium-sized air cylinder is used to control thermo-printing head up and down through electromagnetism valve;

4. The thermo-printing roller is made of 45# steel shaft wrapped with silicon rubber;

5. The infrared quartz pipe is used to heat the blanking roller.

6. It adopts 90YYJ90 gear speed reducer to drive the thermo-printing roller through chain wheels.

7. It adopts stainless steel plate to make reflective board and protective cover.

Preheating unit

1. It adopts 1.5mm cold rolled steel plate to make heating oven and power is 3.2kw;

2. It adopts far infrared quartz pump to heat.

electric panel

It welds by cold rolled steel boards (thickness1.5mm) then finishes by paint. The inside is installed the contactor, inductor, capacitance, fuse, air switch and line bank. The surface of panel is various buttons, knobs, urgent switches, TC and transducers, etc.

Unwinding unit

1. It adopts Q235 steel to weld into wallboard of unwinding;

2. It adopts air bulged shaft as unwinding shafts;

3. The tension is controlled by DZF-2.5 type magnetic powder brake;

4. It adopts duralumin to make the leading roller for running the film.

Main paremeters of PVC ceiling extrusion machine

On-line hot stamping machine based on extruder machine

| Model | Applicable product width |

| SJSZ 51/105 | 160mm/200mm |

| SJSZ 55/110 | 250mm/300mm/400mm/500mm |

| SJSZ 65/132 | 300mm/400mm/500mm/600mm |

| NO. | Machine Name | Quantity |

| 1 | Screw feeder | 1 set |

| 2 | SJSZ series conical twin screw extruder | 1 set |

| 3 | Extrusion Mould | 1 set |

| 4 | Vacuum calibration table | 1 set |

| 5 | Haul-off machine | 1 set |

| 6 | Automatic cutting machine | 1 set |

| 7 | Stacker | 1 set |

| Supporting machine(Optional) | ||

| 1 | High speed mixing machine | 1 set |

| 2 | Hot stamping machine(or Laminating machine) | 1 set |

| 3 | Crushing machine | 1 set |

| 4 | Milling machine | 1 set |

Products Show

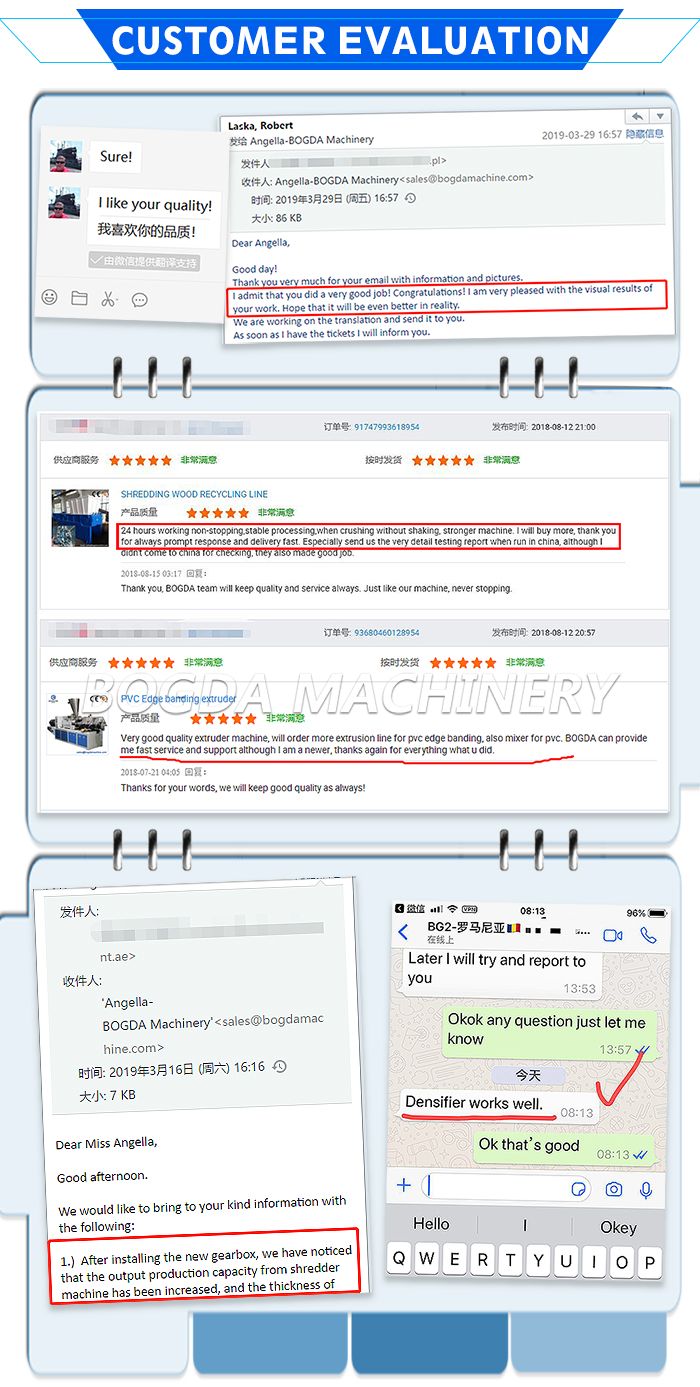

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap