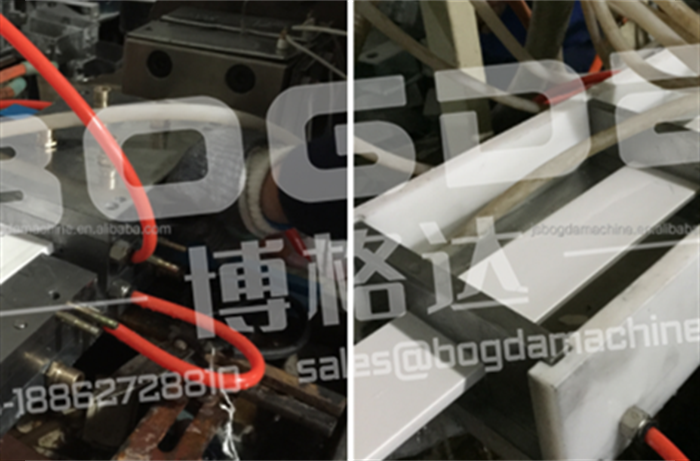

1. High quality extrusion die, is through the reasonable die head and dry mold design and processing precision can make the cavity discharge uniform without dead Angle, thus greatly solve the paste and disassembly mold assembly of the cable and production efficiency. 2. Finalize the design of the set of water and gas routes

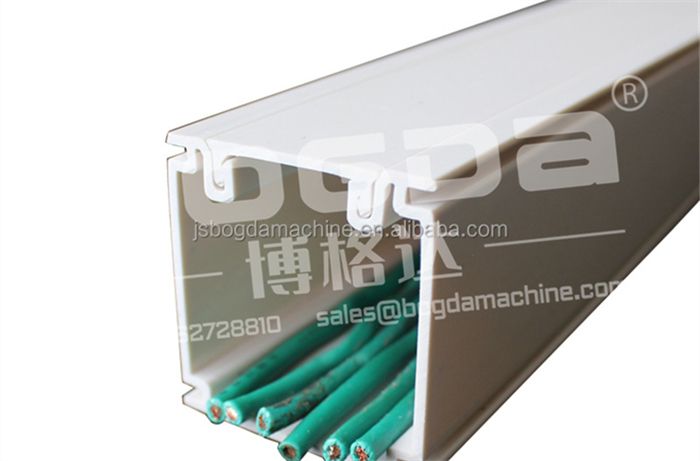

Production Application

Machine Specification

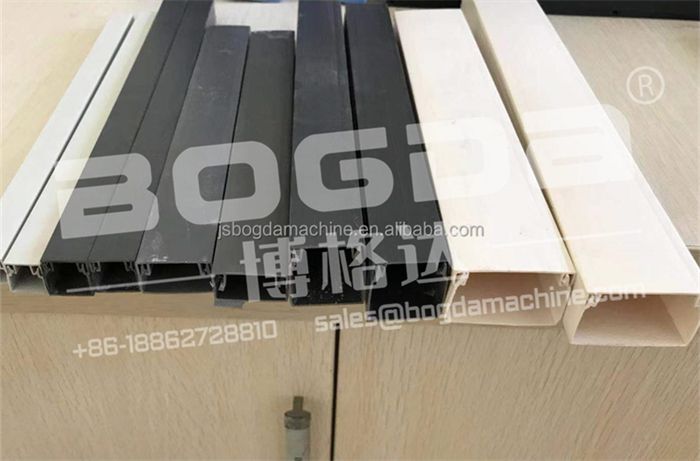

BOGDA Manufacturing PVC Extrusion Profiles Mold For Plastic Trunking Extruder

1. High quality extrusion die, is through the reasonable die head and dry mold design and processing precision can make the cavity discharge uniform without dead Angle, thus greatly solve the paste and disassembly mold assembly of the cable and production efficiency.

2. Finalize the design of the set of water and gas routes, need to reasonably reduce the large area of cooling parts (some matching parts and groove Angle parts).

3. Ensure the depth of each part of the cavity vacuum groove, so that the vacuum suction is uniform, can reduce the internal stress of the profile, to ensure material to achieve the smallest size rate of change after heating.

4. Material of the mold: All of them are made of high quality and high wear-resisting die steel, after strict material conditioning and tempering. Solve the mould life best results.

5. Provide lifelong after-sales service and technical consultation. Warmly welcome customers to visit or call to negotiate.

Product Paramenters

| Size Of One Cavity PVC Extrusion Profiles Mold For Plastic Trunking Extruder | |||

| 40x60mm | 60x60mm | 80x80mm | 100x100mm |

| Extrusion mold include: Die head+Heater+ 400mm CalibratorOther size can be customized. | |||

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap