PVC Extrusion mold is a kind of molding mold, but his way of discharging is to achieve through the action of extrusion.It is widely used in aluminum shaped structure and also in plastic parts.In the front end of the extruder, used for making pipe, or profile.

Production Application

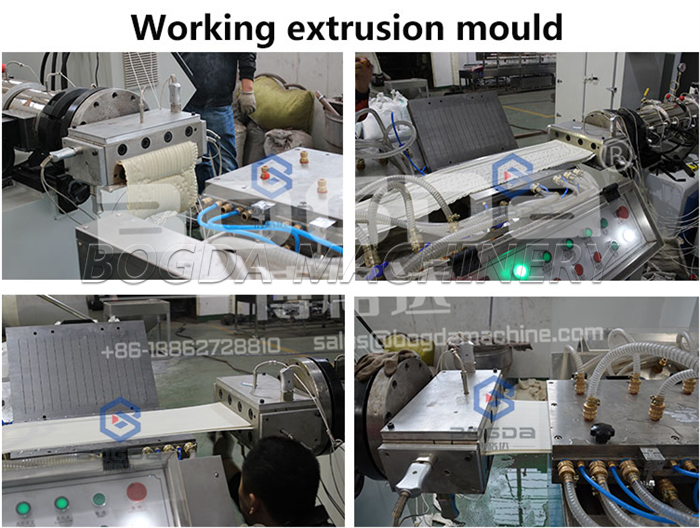

PVC Wall Panel Ceiling Panel Profiles Extrusion Mold Plastic Extrusion Die Design

PVC wall panel has the characteristics of light weight, easy installation, waterproof, moistureproof and moth proof. It also has a lot of pattern changes on the surface, and resistant to pollution, good cleaning, sound insulation, heat insulation of good performance, especially in the new process to add flame-retardant materials, so that it can be removed from the fire is out, use more safe. Its cost is low, adornment effect is good, because this decorates condole to hold important position in material in the family, become the dominant material that the condole such as toilet, kitchen, balcony supports. Condole top is a kind of gimmick that often USES in interior design, the line of sight of people often contacts with it time is more, because this condole carries the shape of the top and artistic processing to affect space effect apparently.

Product Description

PVC Wall Panel Ceiling Panel Profiles Extrusion Mold Plastic Extrusion Die Design

PVC Extrusion mold is a kind of molding mold, but his way of discharging is to achieve through the action of extrusion.It is

widely used in aluminum shaped structure and also in plastic parts.In the front end of the extruder, used for making pipe, or profile. In short, the mold is used to shape the tool, this tool is composed of various parts, different mold is composed of different parts, it mainly through the formation of material physical state change to achieve the shape of the object processing.

The mould is the main processing tool for manufacturing parts in industrial departments such as machinery manufacturing, radio instrument, motor and electric appliance.The quality of die directly affects the quality of pressure processing technology, the precision output of products and production cost. Besides rational structure design and machining accuracy, the quality and service life of molds are mainly affected by mold materials and heat treatment.

1- Surface Style:Flat Type,With Chrome Line,With Recessed Groove in The Middle

2- Panel Section: With Oblique Ribs ; Panel Width: 100mm,120mm,200mm,250mm,300mm

3- Calibration: Wet Calibrator,Dry Vacuum Calibrator,and Water Tank in one set

4- Mould Cavity/Exit: Optioinal

Product Paramenters

| PVC Wall Panel Ceiling Panel Profiles Extrusion Mold Plastic Extrusion Die Design | |

| Ceiling Extrusion Mould Include | Mould die + Calibrator + Heating Zones |

| Ceiling width | 8 inch, 10 inch, 12 inch |

| Calibrator length | 500mm |

| Mould material | 3Cr17 |

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap