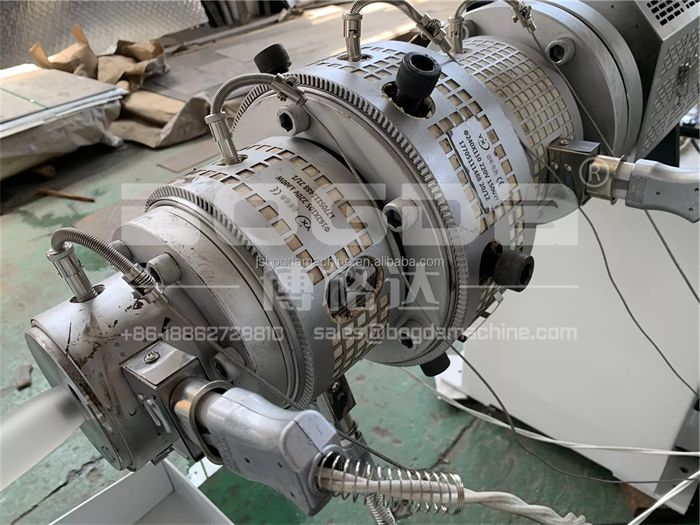

PPR pipe extrusion mould, PPR pipe extrusion mold, PPR pipe extrusion head, PPR tube extrusion die, (spiral die) spiral die characteristics: melt flow speed to achieve the expected mechanical uniformity, thermal uniformity.

Production Application

BOGDA PPR Single Mould Extrusion Tool For Plastic Pipe Extruder

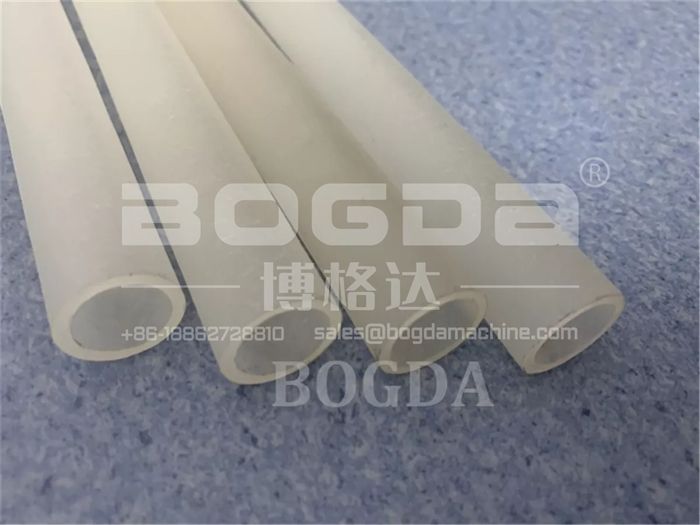

1. As the most ideal hot water supply pipeline for modern (modern decoration renderings), ppr tube is because ppr tube has good heat resistance. It is no problem that the long-term use temperature can reach 75°, and the instantaneous use temperature can reach 95 The insulation effect of .ppr pipe is also good.

2. PPR pipes are smooth inside the pipe and no other particles can be touched. This advantage makes the pipe resistance less and lower energy consumption. The ppr pipe fittings of the same type and material are connected and fused into a perfect whole, avoiding the problem of water leakage in the water pipe.

3. PPR pipe has corrosion resistance, which solves the rust problem of traditional metal pipes. The non-polar material of PPR pipe avoids reaction with other chemical elements in the water. PPR pipe will not scale when used.

4. PPR pipes are lighter in weight. Because of this advantage, the construction difficulty is greatly reduced. As a green environmental protection material, it will not pollute the external environment during production or construction.

Product Description

BOGDA PPR Single Mould Extrusion Tool For Plastic Pipe Extruder

PPR pipe extrusion mould, PPR pipe extrusion mold, PPR pipe extrusion head, PPR tube extrusion die, (spiral die) spiral die characteristics: melt flow speed to achieve the expected mechanical uniformity, thermal uniformity.

1. The screw can be used in the production of inner, middle and outer layers of pipes, and can also be used for pipes of different pressure grades;

2. Low pressure consumption and high output;

3. No mandrel support is needed to eliminate the streamlines in the production process;

4. The diameter above 200 diameter is designed with internal heating thermostat (internal heater and mold temperature machine).

5. Compact structure, reasonable connection, convenient replacement;

6. Made of high quality die steel;

7. The runner is chrome plated and polished so that users can get the best product outer tube.

8. Equipped with mold moving trolley, electric 90° turnover to change mold specifications more convenient and fast.

BOGDA plastic PP PE PPR HDPE PVC UPVC CPVC pipe extrusion mould manufacturing department

Product Paramenters

| BOGDA 20-63mm One Cavity PPR Pipe Extrusion Die Head Mould | |

| PPR pipe mould material | 40Cr/3Cr17/304 SUS |

| Pipe diameter | 20-63mm |

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap