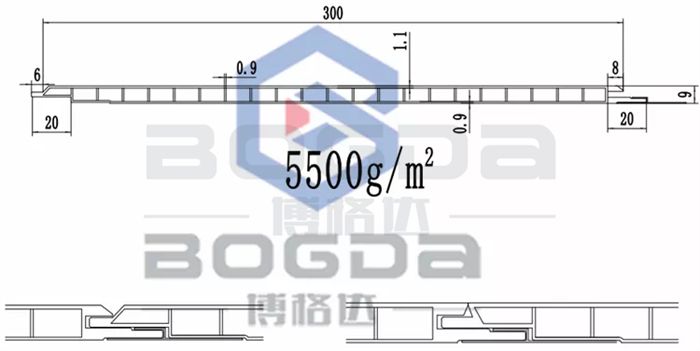

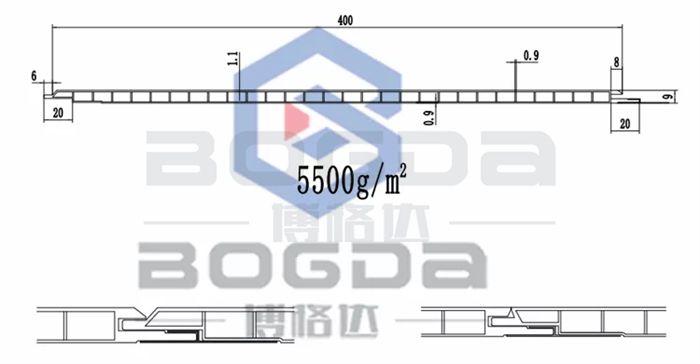

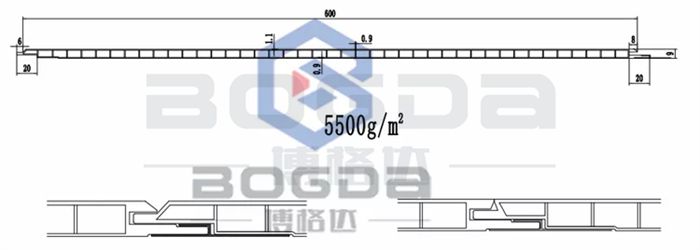

Making PVC Ceiling Panel Extrusion Mould Die , Panel Mould, Ceiling Profile Mould PVC Ceiling Panel Extrusion Mould, PVC Panel Extrusion Moulding for width 100-600mm (Include mould die, heating zones, calibrator and water tank as completed one)

Product Description

We can design different size according to your drawing or samples.

1- Surface Style:Flat Type,With Chrome Line,With Recessed Groove in The Middle

2- Panel Section: With Oblique Ribs ; Panel Width: 100mm,120mm,200mm,250mm,300mm

3- Calibration: Wet Calibrator,Dry Vacuum Calibrator,and Water Tank in one set

4- Mould Cavity/Exit: Optioinal

Main Technical Parameter:

| Mould component | die head, heater ring, calibrator, water tank |

| Mould surface treatment | Hand Polish |

| Production machine | CNC,Drilling,Milling.,etc |

| Product material | PVC, PE, PP, WPC |

| Extrusion speed | 3-5 meter per minute |

| Test | Available |

| Package | Wood case |

| Lead time | 20 days |

| Production ability | 80 sets moulds per month |

| Export to | Kazakhstan, Uzbekistan ,Turkey,Pakistan, South Africa, Russia,andKorea,etc.(we have support office in Kazakhstan) |

Features:

Easy operation

Optimum performance

Durable

Low power consumption

Corrosion/wear resistance

Workshop Photos:

Our Promise:

1- Must TEST each moulds before delivery to confirm good quality with strong wooden case pacakged.

2- Provide good material formulation as customer's reference.

3- Sell competive price with best after-sale.

4- Send testing video & photos for your checking carefully.

5- We will produce PVC Panel Extrusion Line, PVC Mixer, Crusher, Millers, welcome for your enquiry any time.

Auxiliary tools for plastic extrusion mould

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap