(1) It is convenient for feeding, and it is unnecessary to install a forced feeder in the hopper. (2) The relative density of granular material is higher than that of powder material, and the strength of plastic products is better. (3) The mixture of resin and various solid powder or liquid additives is more uniform, and the physical properties of

PVC Pellet Granulation Making Machine

Compared with the direct processing of powder, the advantages of granulated plastics are as follows:(1) It is convenient for feeding, and it is unnecessary to install a forced feeder in the hopper. (2) The relative density of granular material is higher than that of powder material, and the strength of plastic products is better. (3) The mixture of resin and various solid powder or liquid additives is more uniform, and the physical properties of plastic products are more uniform. (4) The color of plastic products is even. (5) The volatile matter of air containing agent in granular material is less, which makes it difficult for plastic products to produce bubbles. (6) Granular material has no pollution to extruder and production environment.

Specification

| NO | Item |

| 1 | Screw Loader |

| 2 | SJSZ80/156 Conical Double Screw Extruder |

| 3 | Pellet Mould 3-5mm |

| 4 | Collector with Blower |

Granulation process is the production process of making granular plastics from high polymer resin, additives and additives through metering, kneading, plasticizing and pelleting. Plastic particles are semi-finished products of plastic molding and processing industry, as well as raw materials for extrusion, injection molding, hollow blow molding, foaming and other molding and processing.

Single screw and twin screw extruders can be used for extrusion granulation. It mainly controls extrusion temperature, screw speed, cutter speed and pellet cooling. The results show that the particle size is uniform and the plasticization is good. The rotation speed of the cutter is adjusted to the length of the granular material 3 ~ 4mm. The screw speed is adjusted to ensure that the particles do not adhere.

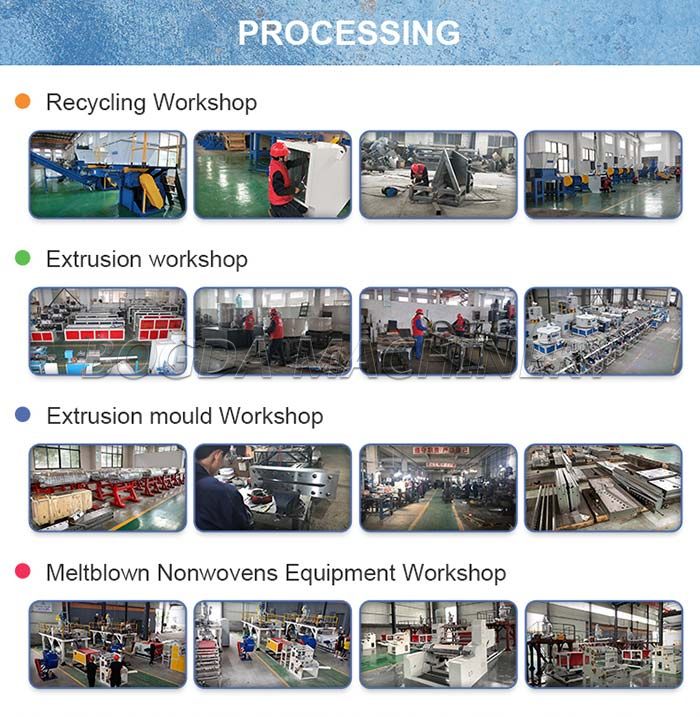

BOGDA Machinery Groupis located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

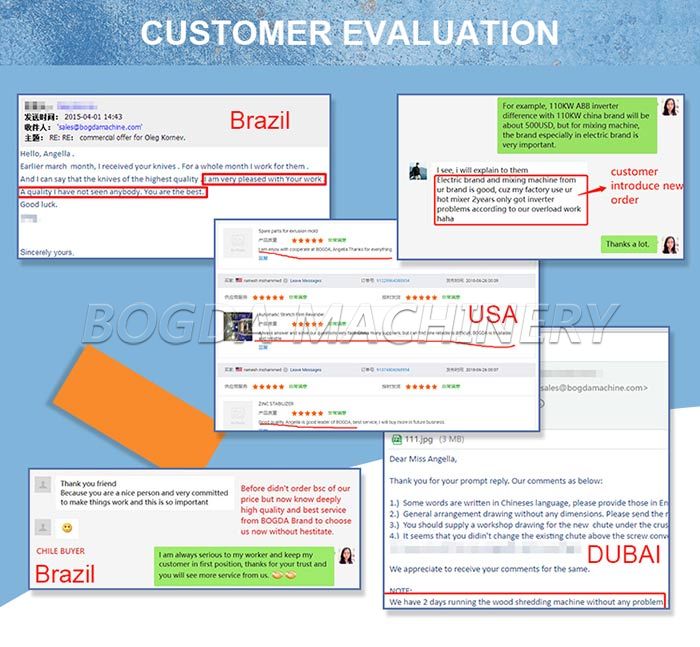

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap