CO2 Foaming Technology XPS Insulation Foam Board Extrusion Production Line has two types:single screw tandem extruder and co-rotating flat twin tandem single screw extruder.

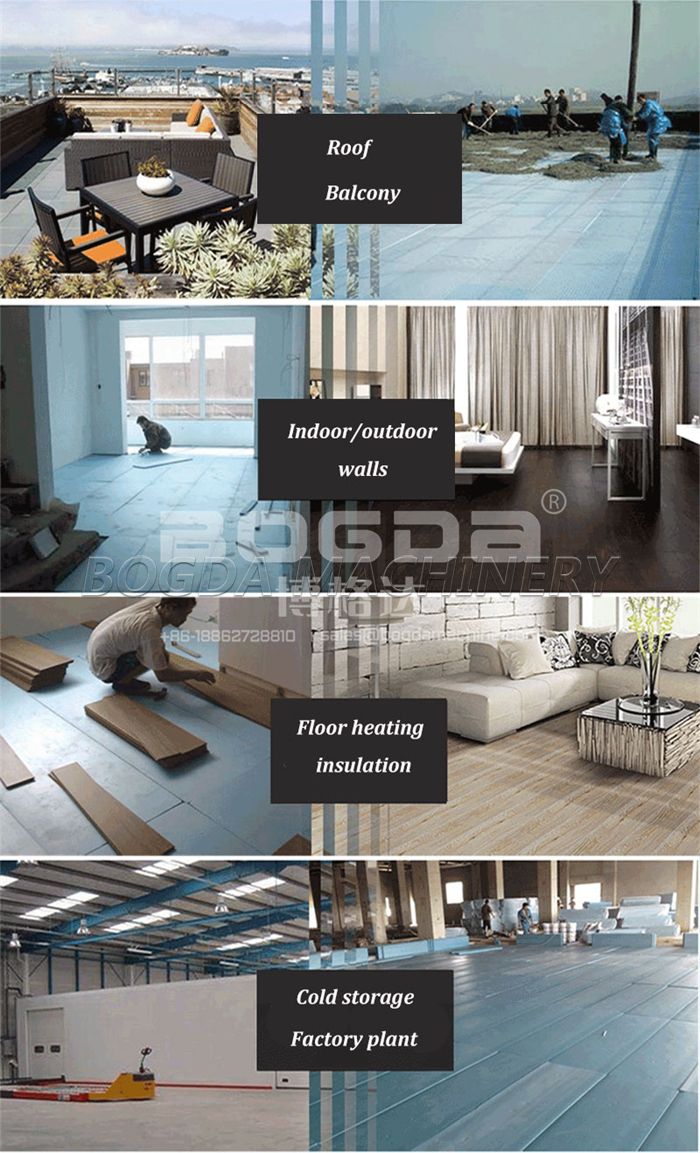

Production Application

Features For BOGDA XPS Foam Board Production Line

1. Thermal insulation

It has the characteristics of high thermal resistance, low linearity, and low expansion ratio. The closed cell ratio of the structure has reached more than 99%, forming a vacuum layer to avoid air flow and heat dissipation, ensuring the

durability and stability of its thermal insulation performance, which is 80% compared to foamed polyurethane The advantages of the closed cell rate are self-evident. Practice has proved that the 20mm thick XPS extruded insulation board has the same insulation effect as 50mm thick expanded polystyrene and 120mm thick cement perlite. Therefore, this material is currently building insulation.

2. High strength and compression resistance

Due to the special structure of XPS board, its compressive strength is extremely high, and its impact resistance is extremely strong. According to the different types and thickness of XPS, its compressive strength can reach 150~500Kpa or more, and it can bear the ground load of various systems.

3. Water-repellent and moisture-proof

Water absorption is an important parameter to measure insulation materials. After the insulation material absorbs water, the insulation performance decreases. In low temperature conditions, the inhaled water is very easy to freeze, destroying the structure of the insulation material, thereby reducing the compression and insulation performance of the board. Because the molecular structure of polystyrene itself does not absorb water, the molecular structure of the board is stable and has no gaps, which solves the problems of water leakage, penetration, frosting, and condensation of other materials.

4. Light texture and easy to use

The completely closed-cell foaming chemical structure of XPS board and its honeycomb physical structure make it light and high-strength, easy to cut and transport, not easy to break, and easy to install.

5. Good stability and corrosion resistance

In long-term use, it does not age, decompose, or produce harmful substances. Its chemical properties are extremely stable, and it will not be degraded due to water absorption and corrosion, and its performance will be reduced. It can still maintain its superior performance in high temperature environments. According to relevant information, XPS extruded insulation board can maintain excellent performance even if it is used for 30-40 years without decomposition or mildew, and no toxic substances volatilize.

Application For High Quality Durable Using Various Machine Production XPS Foam Board Extrusion Line

Building roof insulation, steel structure roofing, building wall insulation, building ground moisturizing, square ground, ground frost heave control, central air conditioning and ventilation ducts, geothermal engineering, highways, airport runways, large-scale cold storage and interior decoration insulation, etc. Fields, etc.

Product Description

High Quality BOGDA XPS Foam Board Production Line

CO2 Foaming Technology XPS Insulation Foam Board Extrusion Production Line has two types:single screw tandem extruder and co-rotating flat twin tandem single screw extruder.

There are 135/150 single screw extruder in series and 75/150 co-rotating flat twin series single screw extruder in specifications. The co-rotating twin-screw extruder can process ingredients composed of many ingredients due to its excellent mixing efficiency.

The carbon dioxide foaming unit produced by BOGDA uses carbon dioxide instead of freon and butane to produce XPS extruded board, which is environmentally friendly and low in cost.

| BOGDA XPS Foam Board Production Line | ||||

| Model | XPS135/150 | XPS75/150 | ||

| Extruder | φ135/32 | φ150/34 | φ75/40 | φ150/40 |

| Motor power | 75/90kw | 55/75kw | 90kw | 55/75kw |

| Products width | 600-1200mm | 600-1200mm | ||

| Products thickness | 20-120mm | 20-120mm | ||

| Capacity | ≥200m³/day | ≥300m³/day | ||

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap