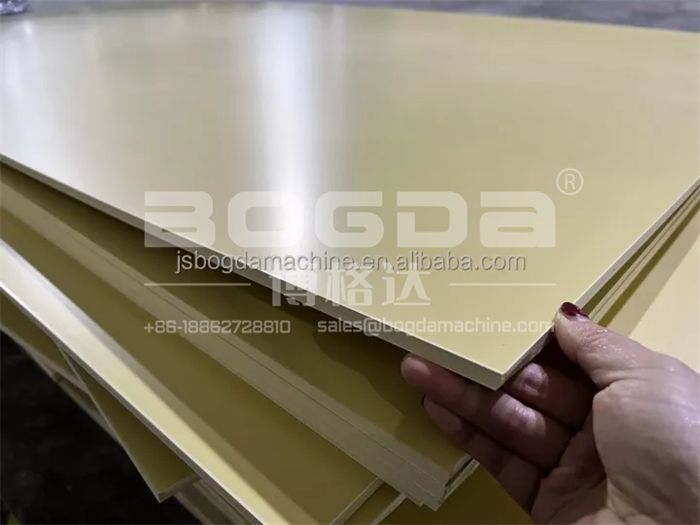

A versatile and durable product, PVC Foam Sheet or expanded PVC is a durable, closed cell, free foam PVC sheet material that combines a rigid exterior and matte finish. Expanded PVC‘s unique characteristics make it ideal for POP displays, signage, kiosks, dimensional lettering, and display boards.

Product Description

WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

A versatile and durable product, PVC Foam Sheet or expanded PVC is a durable, closed cell, free foam PVC sheet material that combines a rigid exterior and matte finish. Expanded PVC‘s unique characteristics make it ideal for POP displays, signage, kiosks, dimensional lettering, and display boards. Expanded PVC has consistent color throughout the sheet and a perfect surface for screen/digital printing, painting, laminating, vinyl lettering and forming applications. This material is found in a variety of interior and limited exterior applications including menu boards, advertising displays, exhibits, and walls.

WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

Available Sizes and Thickness of Sheets:

Standard Sheet Size 8″ * 4″ 3.5mm, 5mm, 8mm, 10mm, 12mm, 12mm, 15mm, 18mm, 20mm, 22mm, 25mm

PVC Foam Board Features and Specifications:

Available In Pleasent Colors

Termite Proof

Excellent Weather Ability

Easy to Fabricate Fine Cell Structure Self Extinguishing Smooth & Semi gloss Can be Applied in half time compare to wood & Ash Wood Waterproof

Recyclable

Light Weight Firm Outer Skin Non Corrosive

High Impact Strength Facility of paint & polish Moisture Proof Thermal insulation Outstanding Printability Low Flame

ability Non Toxic Good Sound Resistance to Vibration

Specification

WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

| NO. | Machine Item |

| 1 | SJZ80 Conical Double Screw Extruder |

| 2 | PVC Foam Board Mould |

| 3 | Calibration Mould Plate |

| 4 | Haul-off Machine |

| 5 | Cutting Machine |

| 6 | Robotic arm |

SJSZ80/156 Conical Double Screw Extruder for WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

PLC Control or Button operation

Mould for WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

Calibration Mould Plate for WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

Press by Hydraulic

Haul-off Machine for WPC PVC Foam Solid Door Board Panel Extrusion Making Machine Production

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap