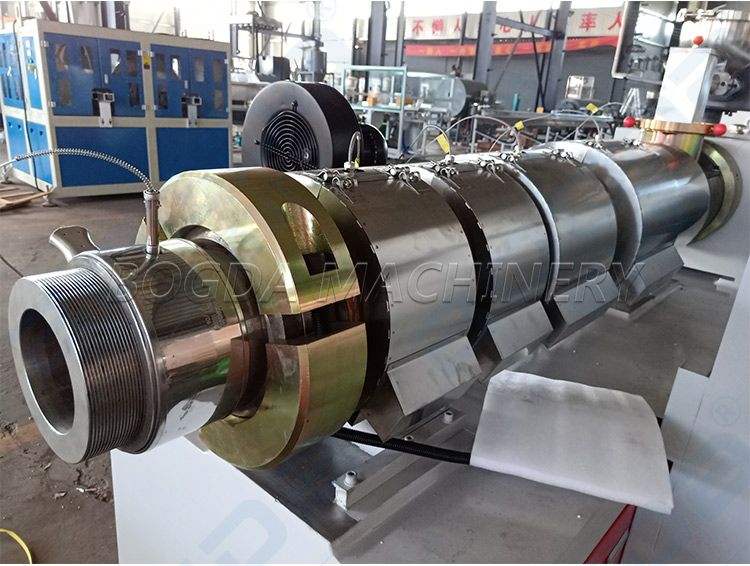

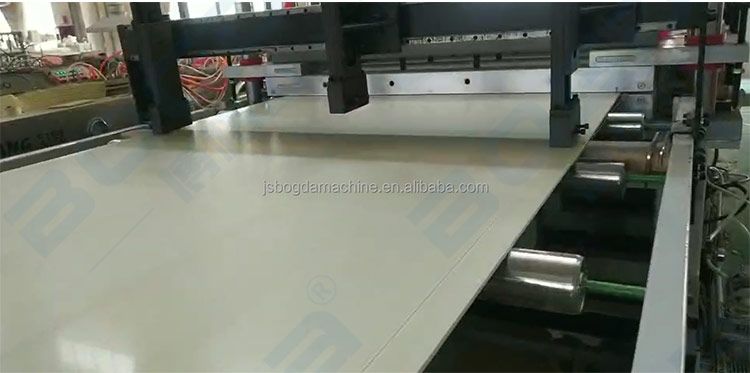

PVC skin-foamed sheet extrusion equipment is composed of parallel-parallel twin screw extruder, sheet extrusion mold, vacuum shaping and ten rollers traction and other auxiliary parts.The extruder adopts SJZ80/156 high output extruder, adopts the new seven-stage pineapple head special foaming screw structure, and the output exceeds 10T in 24 hours.

Production Application

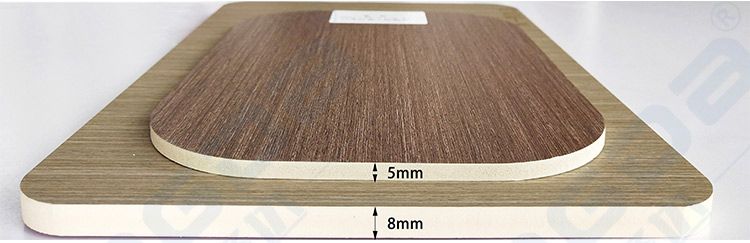

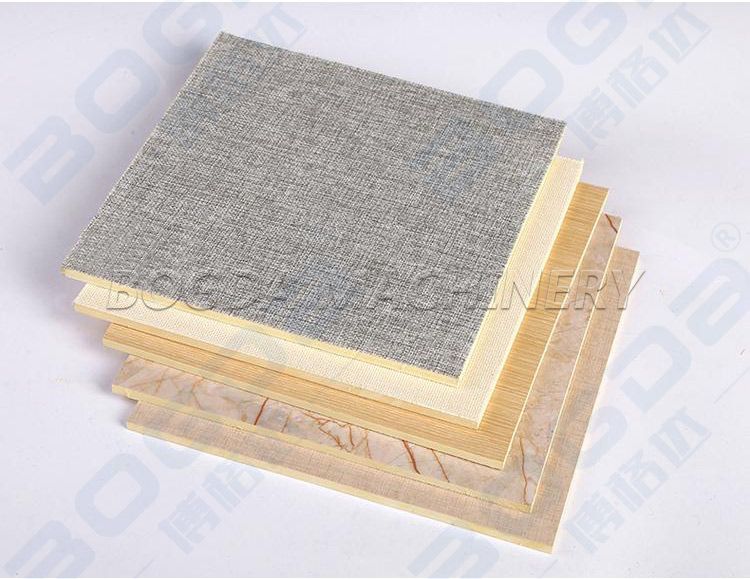

Foamed PVC decoration sheet size

Width: 1220mm Thickness: 5-8mm

Above size is PVC decorations sheet common size, this production also application for free foam sheet, skinned foaming sheet, advertising board, etc. Change the mould to produce different sizes products.

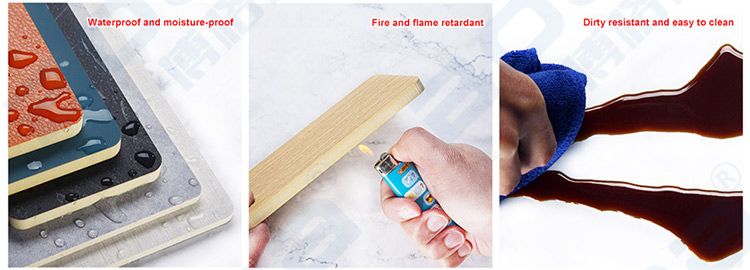

Main advantages of PVC foam decorations sheet

1. Waterproof

2. Fireproof

3. Dirty resistant and easy clean

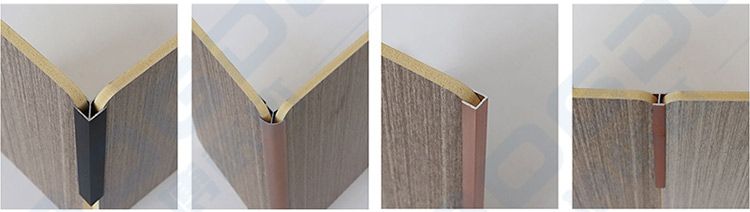

4. Install VERY fast, 1 worker install whole house (120m2) just need 5-7 days. This board installation save labors

5. Beautiful installation effect, market has 2000 kinds differents patterns

Application pictures

The application prospect is very broad. Widely used in cabinet furniture, interior wall decoration, advertising lettering

materials, building decoration materials, automobile, train, ship interior decoration materials, etc

Below picture (the first one is we BOGDA small meeting room with 1220MM foaming PVC sheet)

Machine Specifications

This production also application for PVC decorations sheet, free foam sheet, skinned foaming sheet, advertising board, etc. Change the mould to produce different sizes products.

| NO | Machine Name | Qty |

| 1 | Screw loader | 1 SET |

| 2 | SJZ80/156 Conical twin screw extruder | 1 SET |

| 3 | Extrusion mould | 1 SET |

| 4 | Mold temperature machine | 1 SET |

| 5 | Calibration Forming Machine | 1 SET |

| 6 | Cooling Stacker | 1 SET |

| 7 | Cross Cutting Device | 1 SET |

| 8 | Roller Haul-off Machine | 1 SET |

| 9 | Non-dust Cutting Machine | 1 SET |

| 10 | Automatic Robert Board Lift Machine | 1SET |

| 11 | Electrical control system | 1 SET |

Product Description

Custom Advertisement White PVC Celuka Foam Board Extrusion Machinery Production Line

PVC skin-foamed sheet extrusion equipment is composed of parallel-parallel twin screw extruder, sheet extrusion mold, vacuum shaping and ten rollers traction and other auxiliary parts.

Extruder adopts SJZ80/156 high output extruder, adopts the new seven-stage pineapple head special foaming screw structure, and the output exceeds 10T in 24 hours.

Extrusion flat die head adopts a small die lip on the basis of a common die, and the matching die temperature machine is controlled by the oil, so that the sheet skinning effect is better.

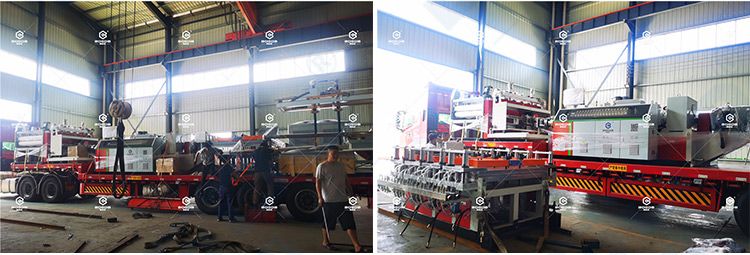

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

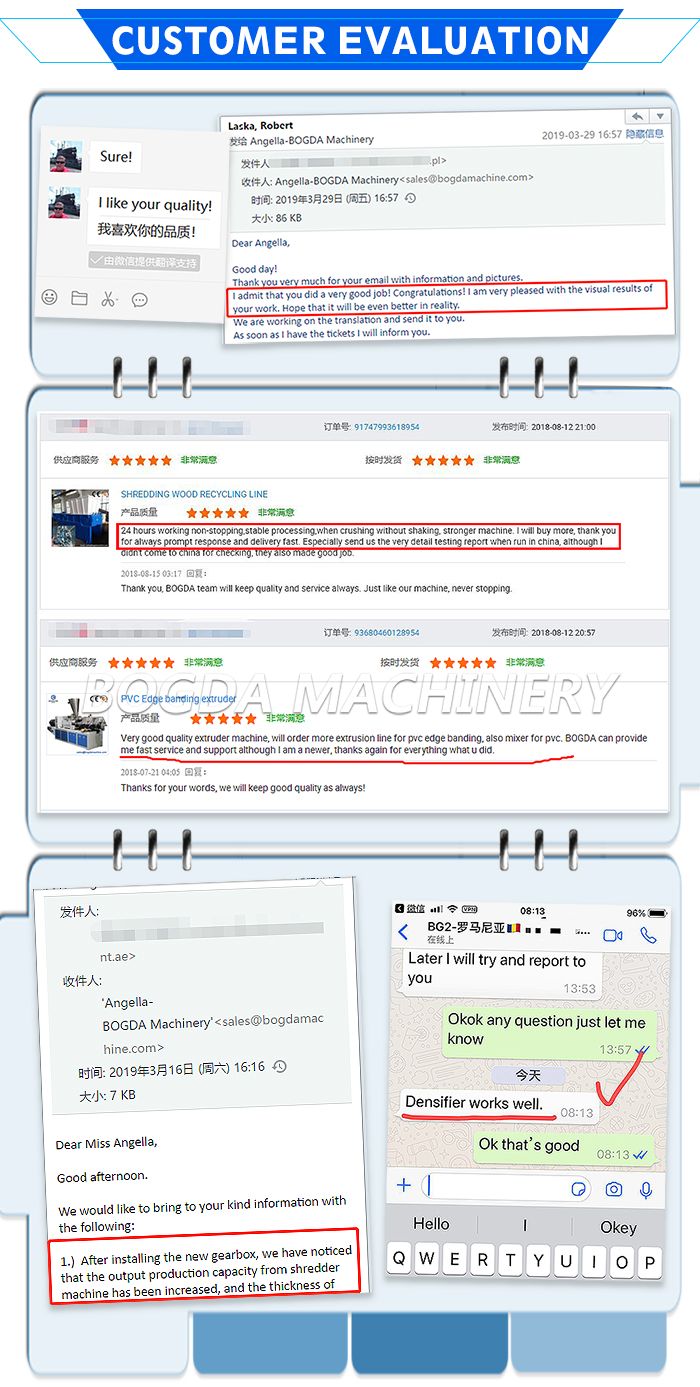

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap