MPP PE orange yellow and white trenchless power tube extrusion line introduction A new generation of MPP power pipe production line, the production line is mainly used to produce 50-250mm MPP power pipe diameter. 1. Extrusion host adopts SJ-PE high-speed screw, slotted feeder barrel, and water jacket cooling of 300mmD

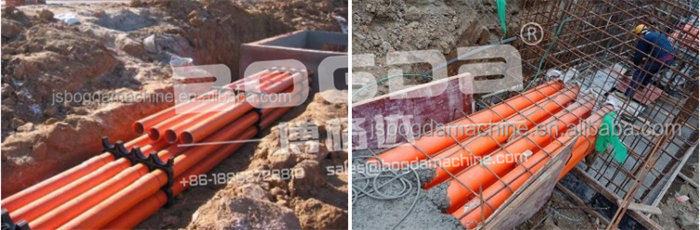

Application of Final Products

What is MPP pipe ?

MPP pipe, also known as MPP power cable protection pipe, is divided into excavation type and trenchless type. MPP trenchless pipe is also known as MPP pipe jacking or drawpipe. The main raw material of MPP tube is modified polypropylene. It has the characteristics of high temperature resistance and external pressure resistance. It is suitable for low and medium voltage power transmission lines and cables under 10kV.

Characteristics For MPP Pipes

The common specification of the pipe is 110mm ~ 250mm in diameter, which is divided into ordinary type and reinforced type. The common type is suitable for excavation and laying construction and trenchless crossing construction with buried depth less than 4M. The enhanced type is suitable for trenchless crossing construction projects with buried depth greater than 4M.

1. MPP tube has excellent electrical insulation. 2. MPP tube has high thermal deformation temperature and low temperature impact performance. 3. MPP tube tensile resistance, compression performance is higher than HDPE. 4. MPP pipe quality is light, smooth, friction resistance is small, can be hot fusion welding butt. 5. MPP tube long-term use temperature of a 5 ~ 70℃.

Application Fields

MPP USES modified polypropylene as the main raw material, is without a lot of dredging, digging and damage to the road surface, in roads, railways, buildings, river bed and other special sections of the pipeline, cable and other construction projects. Compared with the traditional "excavated buried pipe method", trenchless power to meet the environmental requirements of the current pipe engineering, remove caused by the traditional construction of the dust float in the sky, a nuisance factors such as traffic jam, this technique can also be laying pipelines in some areas can not be implemented excavation work, such as sites protected areas, downtown, crops and farmland protection areas, highways, rivers and so on.

unicipal, telecommunication, electric power, gas, water supply, heat and other pipeline projects. 2. Urban and Rural Trenchless Horizontal Directional Drilling and Open Excavation Electric Drainage Projects. 3. Urban and rural trenchless horizontal directional drilling sewer, sewage and drainage pipe projects, industrial wastewater discharge projects.

Product Description

MPP PE orange yellow and white trenchless power tube extrusion line introduction

A new generation of MPP power pipe production line, the production line is mainly used to produce 50-250mm MPP power pipe diameter.

1. Extrusion host adopts SJ-PE high-speed screw, slotted feeder barrel, and water jacket cooling of 300mmD, which greatly improves the conveying capacity and ensures the extrusion;

| Complete MPP Pipe Production Line | ||

| 1 | Raw material feeding system | 1 set |

| 2 | single screw extruder | 1 set |

| 3 | Pipe extrusion mold | 1 set |

| 4 | Calibrator | 1 set |

| 5 | Spray vacuum shaping tank | 1 set |

| 6 | Cooling water tank | 2 set |

| 7 | Ink printer (choosable) | 1 set |

| 8 | Pipe haul off machine | 1 set |

| 9 | Pipe cutting machine | 1 set |

| 10 | Stacker | 1 set |

2. Three layers of mold design, the outer layer of new material is convenient for hot fusion, the inner layer of recycled material to reduce the cost, but also can realize the stress caused by low melt temperature and pipe quality.

3. Vacuum sizing technology and spray cooling water tank are adopted to improve the yield of pipes and meet the needs of high-speed production. Vacuum sizing platform and cooling water tank are made of stainless steel;

4. Adopt three-jaw tractor, upper and lower track synchronous control, frequency conversion speed regulation;

5. No chip cutting machine, smooth cutting surface without burr.

Specification

| Name | Extruder model | Machine dimension (mm) | Max. total power (kw) | Total weight (kg) |

| Single screw extruder | SJ90/30 | 3780X600X3000 | 110 | 6000 |

| Extrusion mold (inner dia.) | 90 | 2000xφ326 | 50 | 1200 |

| 110 | 1500 | |||

| 160 | 1800 | |||

| 175 | 2300xφ440 | 1950 | ||

| 200 | 2100 | |||

| 250 | 2300 | |||

| Forming machine | model 315 | 4300x1750x1800 | 30 | 5000 |

| Cutting machine | Model 315 | 2900x1400x2060 | 7.5 | 2500 |

| Stacker | Model 315 | 5220x2100x830 | 230 |

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap