1. Plastic pulverizer making machine can grind all kinds Hard & Soft materials into 20-80 mesh powders in normal temperature 2. Widely use range, PVC/PE/ABS/PS/PA/PC Materials 3. Plastic pulverizer has a more higher output, 2 or 3 times than normal miller, equip with Dust collector. An ideal energy saving machine in plastic industries

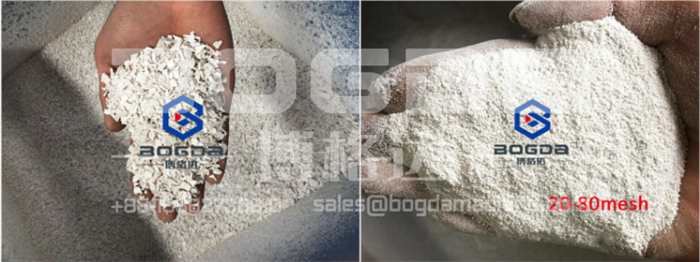

1. Plastic pulverizer making machine can grind all kinds Hard & Soft materials into 20-80 mesh powders in normal temperature

2. Widely use range, PVC/PE/ABS/PS/PA/PC Materials

3. Plastic pulverizer has a more higher output, 2 or 3 times than normal miller, equip with Dust collector. An ideal energy saving machine in plastic industries

4. Includes automatic feeder, main engine, air fan conveying, cyclone separator, automatic shaker screen, auto coarse material milling again,high-efficiency dust collector system. Automatic and space saving.

5. Sword adopted imported stainless steel, durable, can work continous.

6. Plastic pulverizer Knife can be adjusted easily, easily maintained and control

7. Main shaft adopted SKF, matched with oil pump imported, can used about 3-4 years in normal use.

Features of plastic milling machine

1-Compact and space-saving design

2-Low energy consumption and high output

3-Adjustment of the grinding Disc gap from outside

4-Machines by handle and keep the Disc balance

5-Easy changing of the grinding knife

6-Main bearing has water cooling system

7-main grinding room,which is specialized in kinds of material, the grinding knife material is special steel.

8-the machine have fan and air fan to work together.

9-vibrating sieve machine,to become equally powders.

10-all pipe material: stainless steel

11-Hopper:stroge material,keep workshop and machine clean.

Specification

| Model | SMF-500 | SMF-600 | SMF-800 |

| Milling chamber | φ500 | φ600 | φ800 |

| Rotary Blades | 24 PCS | 28 PCS | 36 PCS |

| Main Speed(RPM) | 3900 | 3900 | 3900 |

| Main motor | 37KW | 45KW | 45KW |

| Final powder size | 12-120 micron | 12-120 micron | 12-120 micron |

| Capacity | 150-230kg/hr | 200-350kg/hr | 400-600kg/hr |

| Machine Weight | 1500kgs | 1600kgs | 1800kgs |

| Dimension(mm) | 4200*1450*2900 | 4500*1450*3600 | 4800x1800x4000 |

Machine Details

BOGDA Pulverizer in customer's workshop

1. Belt conveyor for PVC scraps conveying

2. Independent electrical box control, with fan cooling

3. Strong material of machine, connected with raw materials parts are stainless steel

4. For easier installation, each pipe all marked 1, 2, 3.....

Fixed blade and rotating blade

PVC pulverizer in production

Customized type PVC pulverizer

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap