1.The material of machine body is super quality cast steel, not subject to fractures. 2. It is designed for several options of blades, strong in shearing force minimizing of motor load and effective in crushing. 3. The unique design also ensures perfect feeding with large inlet, and low noise with double sound-insulation.

Product Description

Features:

1.The material of machine body is super quality cast steel, not subject to fractures.

2. It is designed for several options of blades, strong in shearing force minimizing of motor load and effective in crushing.

3. The unique design also ensures perfect feeding with large inlet, and low noise with double sound-insulation.

4. Advanced sealing system to effectively prevent leakage of materials from the box, to ensure the service life of bearings.

5. The cutters are made of hign strength alloy and are suitable for cutting various kinds of high strength materials.

6. Material containers are made of stainless steel with wheels undelete durable and convenient for cleaning and moving.

7. Independently controlled electric box

8. Protective guards ensure the safety of the operators.

9. The whole machine system conforms to CE safety standard.

10. The main advantage of the plastic crusher machine is that it saves a lot of cutting labor and cutting waste, saving energy and reducing consumption, and is safe and efficient. The entire system is controlled by the PLC central control system.

Main Usage and Application:

Our plastic crusher machine also can crush other various kinds of materials and meet many crushing requirements such as:

1. HDPE/LDPE/LLD film

2. PP jumpo bags, woven bags

3. Leather, fabrics, nylon

4. Chemical fiber, fishing net, etc.

Main Technical Parameter

| Model | PC-230 |

| Quantity of rotary blades (pcs) | 6 |

| Quantity of stationary blades (pcs) | 2 |

| Motor power (KW) | 4 |

| Diameter of sieve mesh (mm) | 8 |

| Material of blade | SKD-11 |

| Product capacity (kg/h) | 150-200 |

| Transmission method | by belt (B2147X4) |

| Voltage | 380V 50Hz 3Phase |

| Electric brand | Famous brand in China |

| Way of output | Equip with a material truck |

| Specification of machine (mm) | 1000x700x1050 |

| Weight of machine (kg) | about 340 |

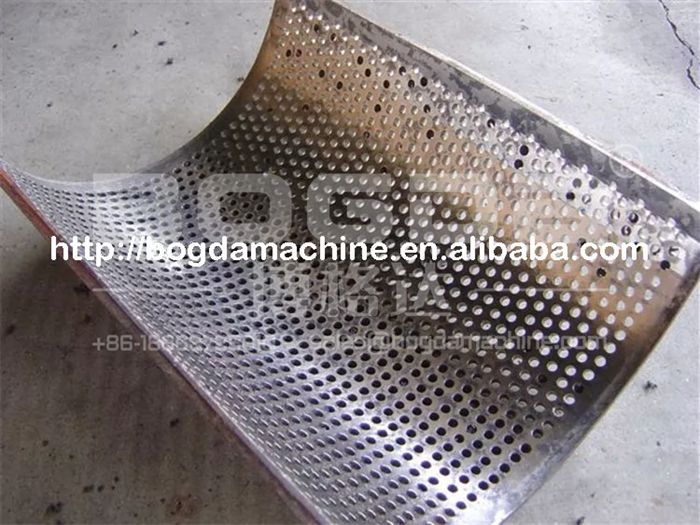

Details of plastic crusher

SKD-11 material crusher blades, toe-in plane knife desigh equipped with high precision bigger diameter roller, effectively crush large quantity film and bags.

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap