With the development of plastic products industry,out company adopts advanced technology for manufacturing heated Air Drier. It is applicable for various plastic shaping machines with high popularities from manufactures of plastic mechanical products. It can save energy by 27-65% and can avoid plastic granule second moisture absorption after drying

Product Description

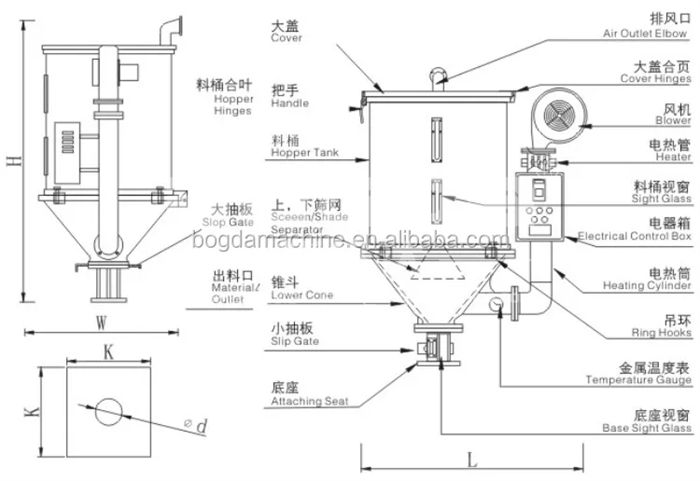

Working principle and descriptions for the hopper dryer machine

With the development of plastic products industry,out company adopts advanced technology for manufacturing heated Air Drier. It is applicable for various plastic shaping machines with high popularities from manufactures of plastic mechanical products. It can save energy by 27-65% and can avoid plastic granule second moisture absorption after drying when driectly linked the material inlet of the main machine.Great in drying ability,and it can increase injection speed rate,the quality of finish products can be improved.

Show details

Products show for plastic dryer from three sides

Features for hopper dryer

Contact parts made of stainless steel

Precisely cast aluminum hull, smooth surface and good performance of maintaining temperature setting

Low noise blower, installed air filter with optional purity guaranteed

Material tank installed with side glass for inspection

Curve heating cylinder designed to avoid the burning caused by powder pile

Installed with proportional deviation display thermostat, to control temperature accurately

High temperature type for 12-1500kg available, with double layer hopper tank, staniless steel heating cylinder, cooling type heater, high temperature resistance blower

Hopper specially designed for easy opening, suitable for all mechanical arm

Hopper dryer details parts

Technical Parameter

| Model | Capacity(KG) | Heating(KW) | Blower(W) | Power(V) | Dimensions(CM) | Base Size(CM) |

| BG-G50KG | 50 | 4.5 | 157 | 220/2p | 87*54*121 | 16*16*ø7 |

| BG-G75KG | 75 | 6.5 | 227 | 380/3p | 94*60*131 | 16*16*ø7 |

| BG-G100KG | 100 | 6.5 | 246 | 380/3p | 101*70*141 | 18*18*ø8 |

| BG-G150KG | 150 | 9 | 350 | 380/3p | 110*74*162 | 20*20*ø8.8 |

| BG-G200KG | 200 | 12 | 350 | 380/3p | 118*84*176 | 23*23*ø11.5 |

| BG-G300KG | 300 | 15 | 750 | 380/3p | 142*100*188 | 27.5*27.5*ø12 |

Working principle show for dryer

Workshop for hopper dryer

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Professional Blade/Knife Sharpening Equipment/machine

Professional Blade/Knife Sharpening Equipment/machine  Industrial Auto Loader Feeding for Extruder Plastic / Plastic Granules Feeding Loader

Industrial Auto Loader Feeding for Extruder Plastic / Plastic Granules Feeding Loader  High Power Industrial Auto Loader Feeding for Extruder Plastic / Plastic Granules Feeding Loader

High Power Industrial Auto Loader Feeding for Extruder Plastic / Plastic Granules Feeding Loader  Vacuum Stainless Steel Container Hopper Loader Sticky Powder Auto Loader

Vacuum Stainless Steel Container Hopper Loader Sticky Powder Auto Loader Copyright © Bogda Machinery Group All Rights Reserved | Sitemap