The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with cooling fan.

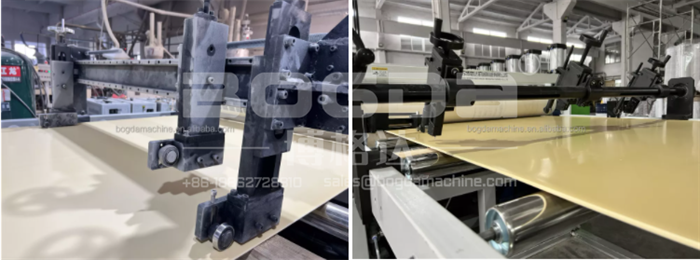

Production Application

Product Description

Countertop High Density Laminated Artificial Marble PVC Celuka Foam Board Production Line

The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with cooling fan.

| Countertop High Density Laminated Artificial Marble PVC Celuka Foam Board Production Line | ||||

| Model | Product Width | Product Thickness | Capacity | Main Motor Power |

| SJSZ80/156PL | 1220mm | 5-40mm | 600kg/h | 75KW |

Extrusion Mould T-die And SIEMENS PLC Touch Screen Control System

1. Die head with streamlined runner surface, two half mold body design, die head disassembly, easy to clean.

2. Manual fine tuning of elastic die lip or movable upper die lip design, extrusion thickness 0.2-1.22mm. Special for lace

products and can be adjusted according to the thickness of products.

3. To adapt to the melt flow of different viscosity to get uniform distribution.

4. Die body adopts die steel or imported alloy steel to prolong the life of the die.

5. All the surface of the runner is plated with hard chromium, the average thickness is 25μm~50μm, and mirror polished. 6. Die head fasteners with high strength bolts of class 12.9.

7. The heating element adopts durable stainless steel heating rod and heating ring

Calibration Forming Machine For PVC Foam Board

Number of set boards: four pairs. Width of shaping board: 1500mm Finalize plate closure: cylinder drive, independent up and down control Plate cooling: water cooling, optimize the design of flow channel Longitudinal movement of setting machine: 0.75 kW reducer motor drive

Cooling stacker with edge side cutting device

Length: 5 m Transition roller: stainless steel, surface polished, hardening treatment

Haul-off machine for pvc foam board

Rubber roller material: polyurethane adhesive Clamping mode: each pair of rollers is pressed by independent cylinder Drive: reducer motor Motor power: 5.5KW, 2 sets synchronous traction Control: Swiss ABB frequency converter

Non-dust Cutting Machine And SUS Stacker For PVC Foam Board

Effective cutting width: 1500mm Cutting method: dust-free blade

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap