The complete Equipment list: 1. Vacuum loader 2. Hopper dryer 3. SJ90/30 single screw extruder 4. SJ50/30 single screw ectruder 5. Extrusion mould 6. Model 400 Vacuum calibrating table 7. Embossing roller machine 8. Traction machine 9. Cutting machine 10. Stacker 11. Color mixer 12. Plascti crusher

Production Application

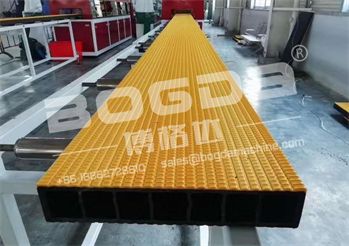

Application for New Type HDPE PE Hollow Board Extrusion Machine Line

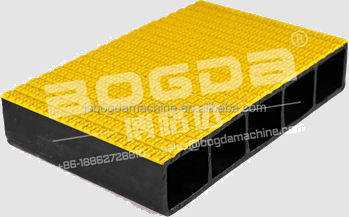

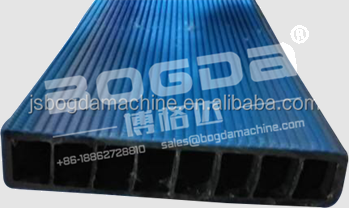

Ocean pedal is made of high-density polyethylene (HDPE, content ≥95%) as the main raw material through extrusion process, which is a new environmental protection product.

The whole product is formed in one step and seamless, which can be connected, fixed, combined and installed into various shapeswith the assistance of other metal or plastic parts according to actual demand or engineering design.

During the production process of ocean pedal, the corresponding antistatic agent, antioxidant, UV anti-uv agent and other

auxiliary materials are added. The whole process is one-step molding, seamless and without water seepage, which conforms to ASTM of American Society for Materials and Testing, CE of European Union and GB national health standards of China.It has the characteristics of anti-oxidation, anti-corrosion, no seawater erosion, no pollution, no damage to the ecological environment and so on.

For wharves, pontoon Bridges, platforms and other places;Suitable for strong sunlight, light (sea) water immersion and other natural environments.

Product Description

Attractive Price New Type HDPE PE Hollow Board Extrusion Machine Line

The complete Equipment list:

1. Vacuum loader

2. Hopper dryer

3. SJ90/30 single screw extruder

4. SJ50/30 single screw ectruder

5. Extrusion mould

6. Model 400 Vacuum calibrating table

7. Embossing roller machine

8. Traction machine

9. Cutting machine

10. Stacker

11. Color mixer

12. Plascti crusher

SJ90/30 single screw extruder

Hardness (HV), 940-1100

Surface finish: Ra≤1.6um

Heating method: ceramic or cast aluminum

Vacuum calibratiing table

Setting table length: 12 m

Water tank material: stainless steel

Width: 1000-1200 - mm

Embossing machine

Can be customised according to customer's requirements

Traction machine

Motor: 2.2KW *2

Frequency control: ABB

Automatic cutting machine

Cutting method: saw cutting

Saw blade material: alloy steel

Cutting motor: 3kW

Suction fan: 2.2KW

Mobile motor: 0.75KW ABB inverter control

Different Patterns For PE HDPE Marine Breeding Pedal Extrusion

Specification

| Model | Designed extrusion output (kg/h) | Product Width (mm) | Product Thickness (mm) | Main motor power (kw) | Speed | Color |

| SJ90/30 | 250-300 | 400 | 75-80 | 75 | 12-20 M/Hr | black+yellow |

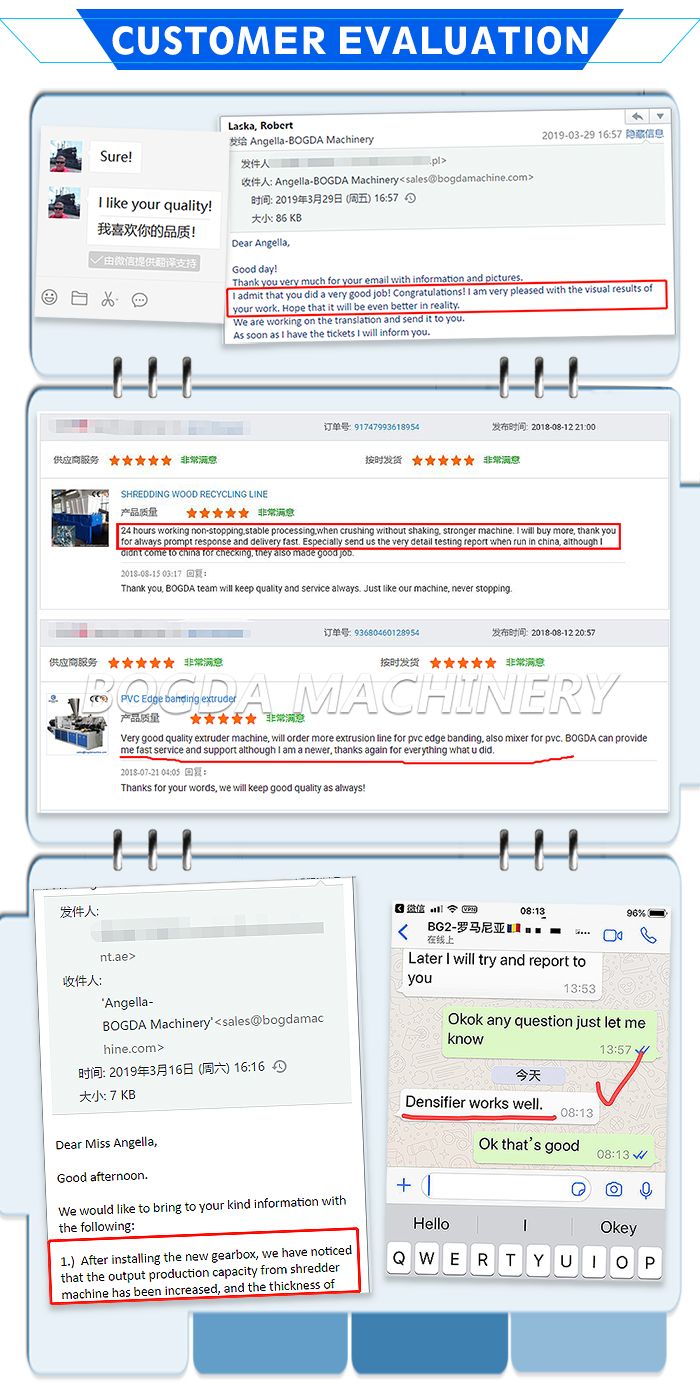

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap