Using the opposite cone type twin screw extruder, adapt to the wood powder, plant fiber specific gravity small, large filling requirements

Production Application

What is WPC Composite Door?

Wood plastic door is with natural high quality wood powder and polyvinyl chloride (PVC) be main raw material, use nanometer technology and micro foaming technology, classics classics high temperature high pressure extrudes the set door that form. The production process of WPC does not contain formaldehyde and other harmful substances, and it is a double environmental protection product in the real sense (there is no harmful pollution in the production process and the product itself). Wood plastic door has both solid wood door and composite wood door double characteristics, especially: zero formaldehyde, waterproof, flame retardant, corrosion resistance, anti-moth, light weight, high strength, no cracking, no deformation, green environmental protection and recycling and other excellent characteristics. The product is a new environmental protection product which can save energy and recycle resources. Wood plastic door convenient installation, door line and door using bayonet connection, without nails and adhesive fixed; The wood-plastic door material has the processing performance of solid wood, which can be planed, sawed, drilled, milling, sticky, and can be processed according to the size of the door body; Its uniform and fine bubble and cavity structure ensures the low thermal conductivity and excellent noise reduction performance of the wood-plastic door.

Product Description

SJSZ80/156 PVC/WPC Foam Door Board Production Machine

Wood Plastic Composite Door Panel Extrusion Line

Using the opposite cone type twin screw extruder, adapt to the wood powder, plant fiber specific gravity small, large filling requirements.

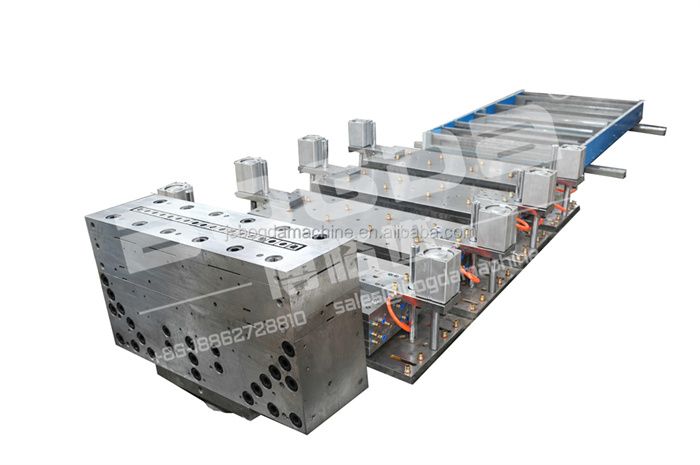

Extrusion mould for pvc wpc hollow door panel

The die head is connected to the molding part of the front end of the extruder barrel. It is a device for the melting material to be compressed to the die after extrusion by the extruder. The die head is mainly composed of flange, die body, support plate, shunt head, mandrel and die. The mold is strong enough under the pressure of molten plastic and easy to assemble and disassemble to ensure reset accuracy and maintenance.

Vacuum calibration mould and cooling water tank

Vacuum shaping adopts special eddy current cooling system to facilitate cooling and shaping, in order to meet the needs of the production characteristics of wide wood plastic board.

The molten billet extruded from the die head is pulled into the mold cavity, which is close to the cavity wall under the action of vacuum adsorption force, and is cooled and solidified by heat exchange of cooling water flowing in the mold. The accurate mold cooling uniform heat conduction efficiency is high, and can move the precise product size.

Haul-off machine for pvc wpc hollow door board

The tractor adopts unique technology, stable work, good reliability and high traction force.

Horizontal cutting device and plate traction speed to keep synchronous, reasonable design, stable operation, can automatically determine the size of cutting, and equipped with dust recovery device.

Final PVC WPC Composite Door Panels

Door width: 700, 800, 950, 1000,1250mm or customised

Door thicknesss: 40mm or customised

Product Paramenters

| SJSZ80/156 PVC/WPC Foam Door Board Production Machine Wood Plastic Composite Door Panel Extrusion Line | |

| Model | SJSZ80/156 |

| Screw diameter | φ80, φ156 |

| Screw quantity | 2 pcs |

| Screw speed | 1-37.7r/min |

| Main extruder power | 55kw |

| Heating power | 36kw |

| Capacity | 150-350mm |

| Porduct width | ≤700mm |

| Product thickness | 40mm |

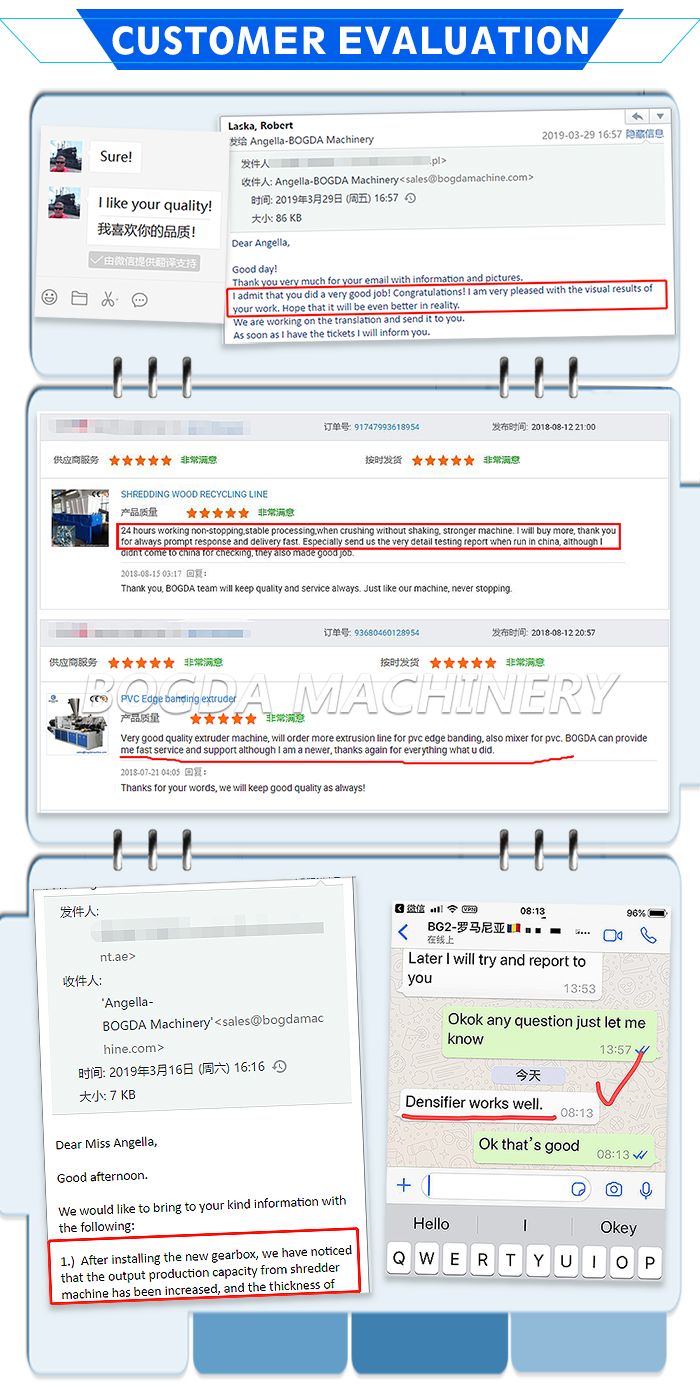

BOGDA Machinery Group is located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap