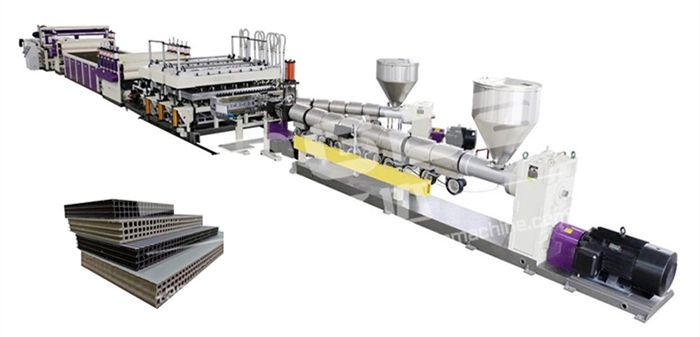

PP plastic building template production line equipment production of plastic building template, can add straw, corn cob, wheat pole, sawdust and other powder, mixed in PP raw materials through special process to produce a variety of new construction template for construction site needs.

Application of Plastic PP Hollow Construction Building Formwork Template Board

Plastic building formwork is an energy-saving and environmentally friendly product. It is another new generation product after wood formwork, combined steel formwork, bamboo-wood glued formwork, and all-steel large formwork. It can completely replace the traditional steel formwork, wooden formwork and square timber, energy saving and environmental protection, and low amortization cost.

Plastic PP Hollow Construction Building Formwork Template Board Advantage

Good water resistance.Even if it is completely immersed in water for many days, it will not be deformed by dampness.It will not rot and rust. 2. It is not friendly to cement and is sticky. It is easy to remove the mold after construction and will not be deformed due to cement adhesion. 3. High construction efficiency and good quality.The surface of the building constructed with it is smooth and smooth, without secondary modification. 4. The working procedure is saved and the construction efficiency is improved.At the same time, the surface of the template can be pretreated to get the desired metope pattern. 5. Light weight, convenient construction and high efficiency. 6. High support strength, not easy to deform. 7. Low cost. 8. Long life and repeated use.The final damaged plastic template can still be smashed again and reprocessed into a new template, saving resources and meeting the requirements of "Green industry "Requirements. 9. Good thermal insulation, which is conducive to shorten the construction period.

Specification

Plastic PP Hollow Construction Building Formwork Template Board Extrusion Making Machines Equipment

PP plastic building template production line equipment production of plastic building template, can add straw, corn cob, wheat pole, sawdust and other powder, mixed in PP raw materials through special process to produce a variety of new construction template for construction site needs. This machine consists of two single screw extruder, hydraulic net changer, mould, setting machine, primary tractor,annealing furnace, cooling box, secondary tractor, cross cutting machine and conveyor.

| 1 | SJSZ-120/36 Single screw extruder |

| 2 | SJSZ80/33 Single screw extruder |

| 3 | Hydraulic screen changer |

| 4 | Distributor |

| 5 | Mold (customized by client requirement) |

| 6 | Vacuum calibration table |

| 7 | First haul-off device |

| 8 | Cooling bracket |

| 9 | Second haul-off device |

| 10 | Cutter |

| 11 | Cutter |

Mould for Plastic PP Hollow Construction Building Formwork Template Board Extrusion Making Machines Equipment

1- Width: 1220mm

2- Thickness:15-18mm

3- 13 zones

4- Alloy Steel

| Thickness | Size | Weight | Area |

| 15mm | 915mm*1830mm | 13.5kgs+_0.5kgs | 1.67m2 |

| 15mm | 1220mm*2440mm | 24.5+_0.5kgs | 2.98m2 |

| 17mm | 915mm*1830mm | 14.5+_0.5kgs | 1.67m2 |

| 17mm | 1220mm*2440mm | 25.5+_0.5kgs | 2.98m2 |

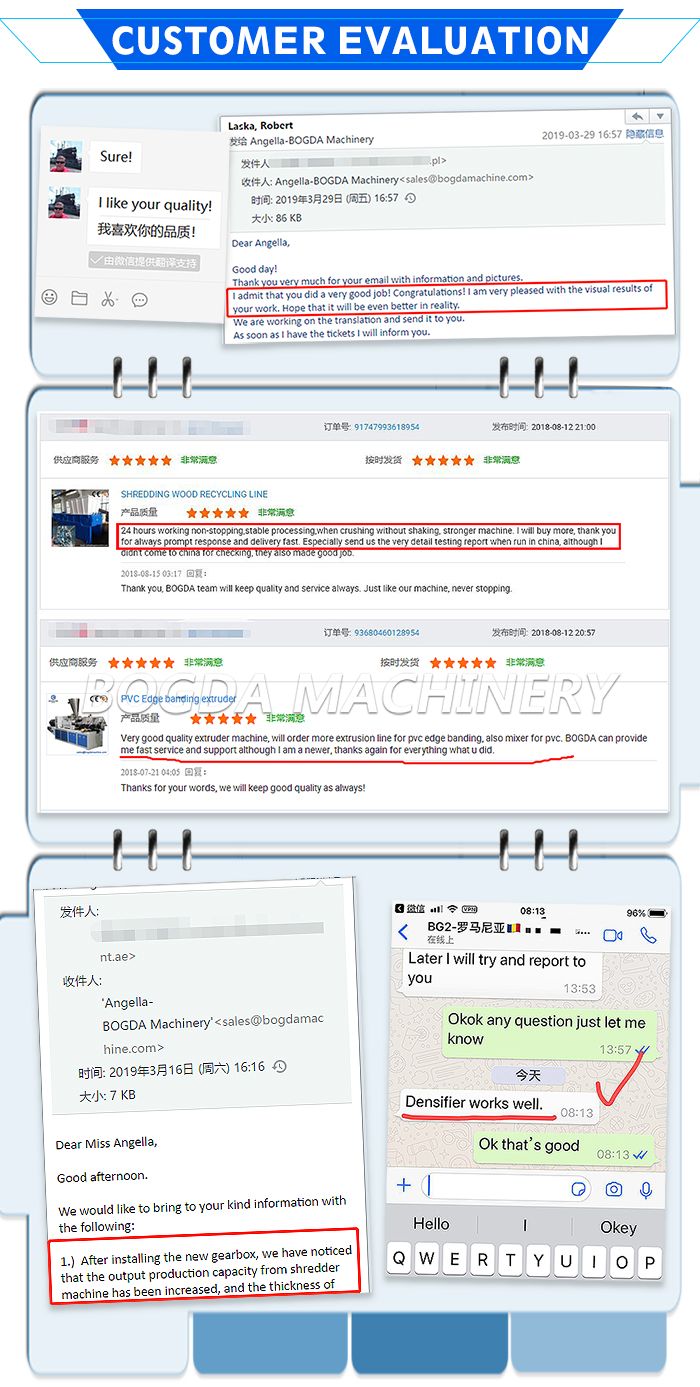

BOGDA Machinery Group is located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap