The screw was designed by special mixed material and high plastify, so that flux plastic, coliury, high output. T-die was designed by special double threttle, it make sure sheet thichness more nicety. Temperature control + 1/-1, itwill exactly control plastify process, sheet thickness.

Production Application

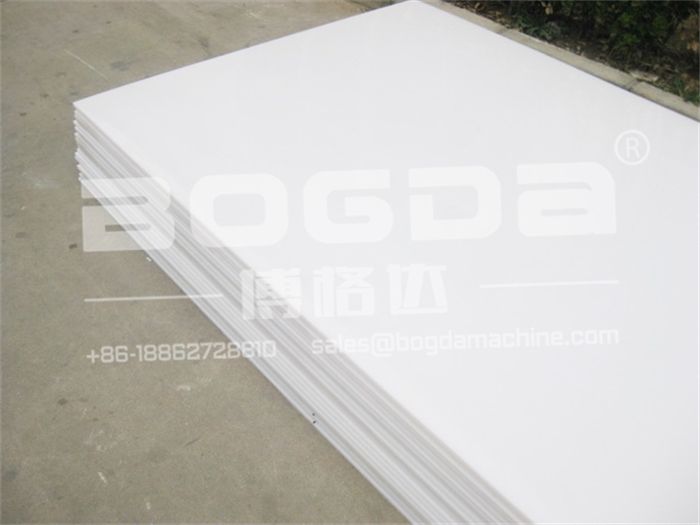

PP thick plate extrusion production line

PP thick plate is a kind of environmental protection products, widely used in chemical industry, food industry, corrosion

resistance industry, environmental protection equipment industry and so on.

PE thick plate extrusion production line

PE board is widely used in chemical industry and power industry.HDPE boards are known as engineering plastics and are used in mechanical and chemical equipment as well as hockey ring walls.

ABS thick plate extrusion production line

ABS thick plate is widely used in household appliances, electronic products, packaging, medical equipment.

PVC thick plate extrusion production line

Rigid PVC thick plate is widely used in chemical industry, gasoline, electroplating, water purification equipment, environmental protection equipment, light box, advertising, etc.

Product Description

The screw was designed by special mixed material and high plastify, so that flux plastic, coliury, high output.

T-die was designed by special double threttle, it make sure sheet thichness more nicety.

Temperature control + 1/-1, itwill exactly control plastify process, sheet thickness.

Forming roller paltform adopts vertical or 45 degree inclined collocation, which can lift up and down, it supplies more options in operation for producting think board thin board, and rnhance quality of board.

Forming roller loop cooling system, matching with mould temperature controller to control teperrature, which ensures even

thichness of loard.

Shearer can precisely cut the board.

Winder device, which adopts high grade torque motor, motching with four-axis automatic tension controling, which can adjust speed and winding tension to get even surface for thin board, also with slitting device can set widh of product as you want, we fix anuomatic meter counter which can set the length of product.

Specification

| Model | Material | Width | Thickness | Capacity |

| SJ-90 | PP/PE/ABS | 1220mm | 2-20mm | 300kg/h |

| SJ-120 | PP/PE/ABS | 1220-1600mm | 10-40mm | 400kg/h |

| SJ-150 | PVC | 1200-2000mm | 10-60mm | 500kg/h |

| SJZ-80 | PVC | 1200-2000mm | 10-25mm | 400kg/h |

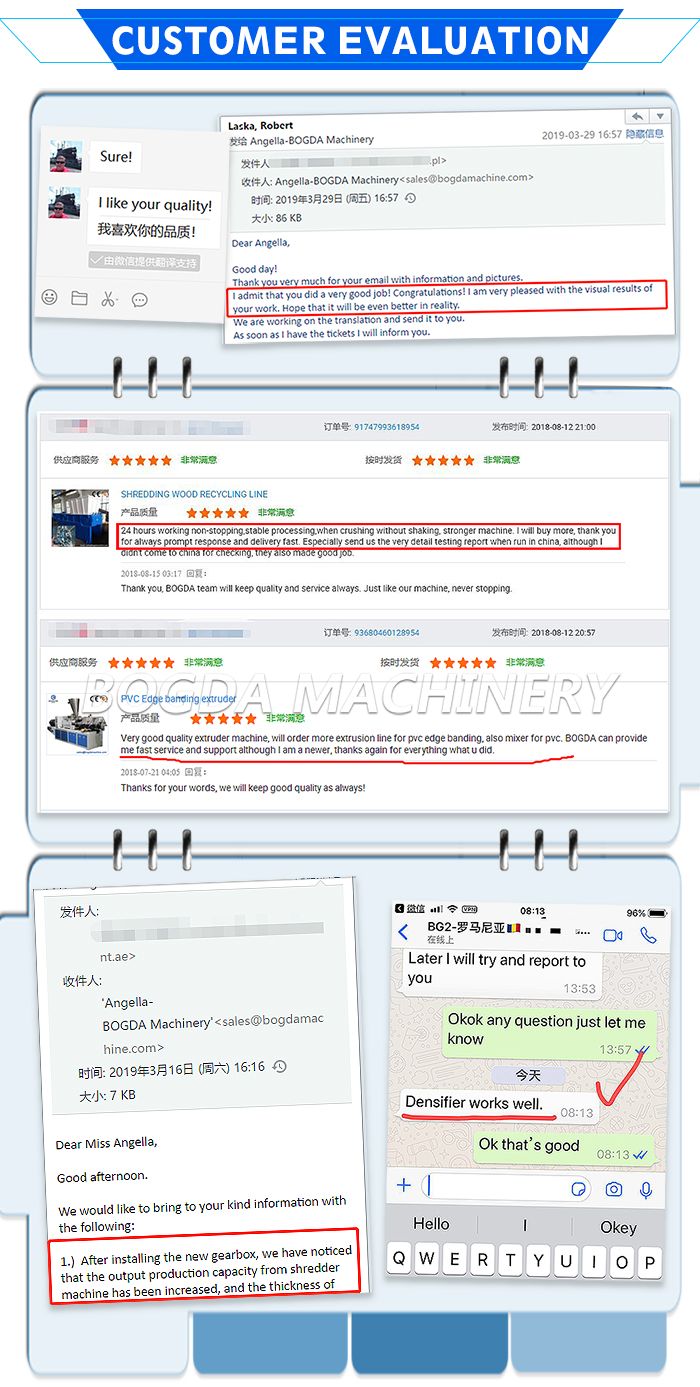

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic

granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported

machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap