The single screw extruder is mainly composed of three parts: extrusion system, transmission system and heating and cooling system. The main function of the extrusion system is to melt and plasticize the polymer material to form a uniform melt and realize the transition from the glassy state to the viscous state

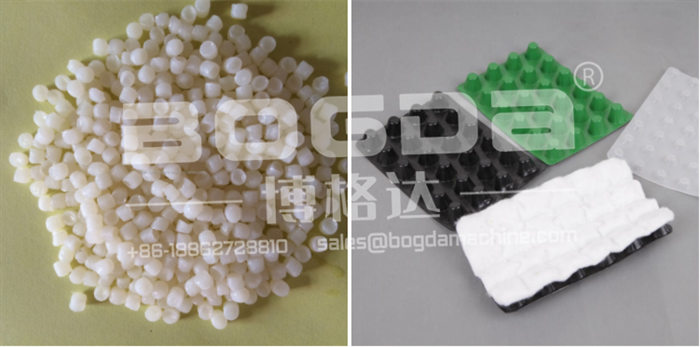

Production Application

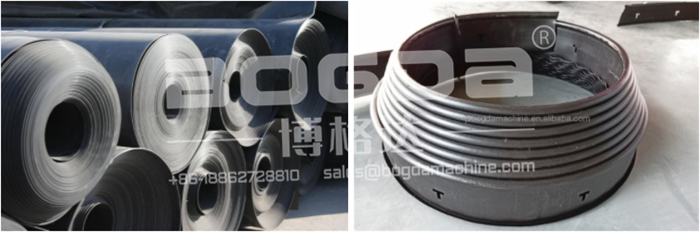

Application For Large PE HDPE Geomembrane Sheet Extruder HDPE Water Stop Sheet Extruding Machine

1. Pipe extrusion: suitable for PP-R pipe, PE gas pipe, PEX crosslinked pipe, aluminum plastic composite pipe, ABS pipe, PVC pipe, HDPE silicon core pipe and various co-extrusion composite pipe.

2. Sheet extrusion: suitable for PE HDPE PP sheet extrusion.

Product Description

PE HDPE Geomembrane Sheet Extruder HDPE Water Stop Sheet Extruding Machine

The single screw extruder is mainly composed of three parts: extrusion system, transmission system and heating and cooling system.

Extrusion system for single screw extruder

The main function of the extrusion system is to melt and plasticize the polymer material to form a uniform melt and realize the transition from the glassy state to the viscous state. In this process, a certain pressure is established, which is continuously extruded by the screw and conveyed to the machine head mold. Therefore, the extrusion system plays an important role in the molding quality and output of extrusion process. Extrusion system mainly includes feeding device, screw and barrel and other parts, it is the most critical part of the extruder, the screw is the heart of the extruder, the material through the rotation of the screw to move in the barrel, and get pressurization and part of the heat.

Transmission system

Transmission system is usually composed of motor, reducer and bearing, its role is mainly to drive the screw, the supply of torque and torque required by the screw in the extrusion process. In the extrusion process, the screw speed is required to be stable, and does not change with the screw load, to ensure uniform quality of products. But in different occasions, the screw can achieve variable speed, in order to achieve a device can adapt to the extrusion of different materials or different shapes of products requirements. In most extruders, the change of screw speed is realized by adjusting the motor speed, and the transmission system is also equipped with a good lubrication system and a quick braking device.

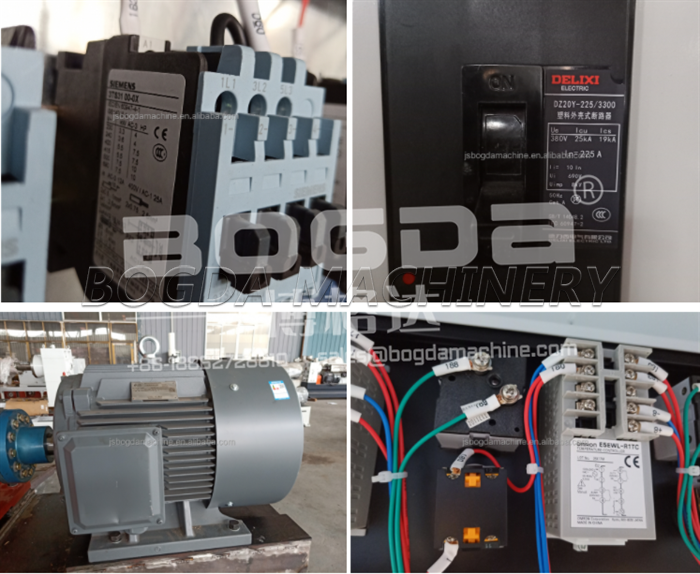

Equipped with famous brand electrical appliances, not easy to broke.

ABB, Omron, DELIXI, SIEMENS......

Heating and cooling systems

The heating and cooling system of the extruder is composed of heating device and cooling device, which is the necessary condition for the extrusion process to proceed smoothly. The heating device and cooling device must ensure the melting and plasticizing of polymer materials and the temperature conditions in the molding process to meet the technological requirements. The cooling device is generally arranged in the material barrel, screw and the bottom of the hopper of the extruder. The cylinder can be cooled by water or air. Generally, the small and medium-sized extruders are mostly cooled by air. Large extruders mostly use water cooling or a combination of the two forms. Screw cooling mainly adopts central water cooling, the purpose is to increase the material solid transport rate, stabilize the amount of material, and improve the quality of products. The cooling device at the bottom of the hopper is mainly to strengthen the conveying effect of solid materials, to prevent the material particles from sticking due to the temperature rise, blocking the material mouth and then affecting the feed. Generally for extruders with screw diameter of more than 90mm and high-speed extruders, the cooling device must be set at the bottom of the hopper.

Specification

| Reference Parameter For Single Screw Plastic Extruder | |||||||||

| Extruder model | SJ30 | SJ45 | SJ55 | SJ65 | SJ75 | SJ90 | SJ100 | SJ120 | SJ150 |

| Screw Diameter (mm) | 30 | 45 | 55 | 65 | 75 | 90 | 100 | 120 | 150 |

| L/D | 25-30 | ||||||||

| Main motor power (kw) | 5.5 | 11 | 15 | 30 | 45 | 55 | 75 | 90 | 132 |

| Barrel heating power | 3 | 6 | 9 | 12 | 18 | 30 | 36 | 42 | 56 |

| Central height (mm) | 1000 | 1100 | 1200 | 1300 | |||||

| Screw rotation speed (r/min) | 140 | 120 | 100 | 90 | 85 | 75 | 70 | 60 | 60 |

| Plasticization capacity (kg/h) | 30 | 50 | 70 | 80 | 100 | 130 | 160 | 200 | 300 |

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

PVC Ceiling Panel Making Machine with Online Printing / PVC Ceiling Machine

PVC Ceiling Panel Making Machine with Online Printing / PVC Ceiling Machine  BOGDA PVC WPC floor skirting board foam baseboard extruder PVC profile extruder machine

BOGDA PVC WPC floor skirting board foam baseboard extruder PVC profile extruder machine  SJ25 Single Screw Small Plastic Co-extruder Lab Small Test Extruder

SJ25 Single Screw Small Plastic Co-extruder Lab Small Test Extruder  Plastic PP PE PPR PC ASA Pipe / Profile Single Screw Extruder Lab Extruder

Plastic PP PE PPR PC ASA Pipe / Profile Single Screw Extruder Lab Extruder Copyright © Bogda Machinery Group All Rights Reserved | Sitemap