Taper twin screw extruder has the characteristics of homogenous plasticizing, high yield, stable quality, wide range of application, long service life, direct molding of PVC powder, etc.

Production Application

Wide WPC Foam Board Wall Panel Extruder Machine

Taper twin screw extruder has the characteristics of homogenous plasticizing, high yield, stable quality, wide range of application, long service life, direct molding of PVC powder, etc.

With the corresponding molding head mold and auxiliary machine, it can directly extrude all kinds of thermoplastic plastics, especially hard polyvinyl chloride powder, into plastic products such as tubes, plates, sheets, bar, films and profiles, and can also complete the modification of all kinds of plastics and the process of powder granulation.

Product Description

Wide WPC Foam Board Wall Panel Extruder Machine

The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with cooling fan.

The specially designed transmission part adopts the new frequency conversion motor drive or direct drive current motor, which has the advantages of stable operation, large transmission torque and high efficiency.Stepless and stable speed regulation can be achieved through imported frequency converter or DC governor, with high precision and energy saving. Adopt intelligent double display digital temperature controller with high control precision and small temperature fluctuation.

Equip with overload protection and fault alarm, screw core part oil circulation constant temperature, barrel oil cooling and other functions, and equipped with vacuum exhaust pipe device and quantitative feeding device.

We BOGDA is a factory to manufacture various plastic extruder, include single screw extuder, double screw extruder, parallel twin screw extruder and related extrusion line.

Product Paramenters

Extruder | SJSZ45 | SJSZ51 | SJSZ55 | SJSZ65 | SJSZ80 | SJSZ92 |

Screw Diameter (mm) | 45/90 | 51/105 | 55/113 | 65/132 | 80/156 | 92/188 |

Screw speed (r/min) | 1-45 | 1-45 | 40 | 1-35 | 1-37 | 1-33 |

Power (kw) | 15 | 18.5 | 22/30 | 37 | 55 | 90 |

Direction of screws | Screw rotation direction | |||||

Capacity (kg/h) | 120 | 80-150 | 150-180 | 250-300 | 320-400 | 600-800 |

Weight (kg) | 2800 | 3200 | 3500 | 4000 | 5000 | 8000 |

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

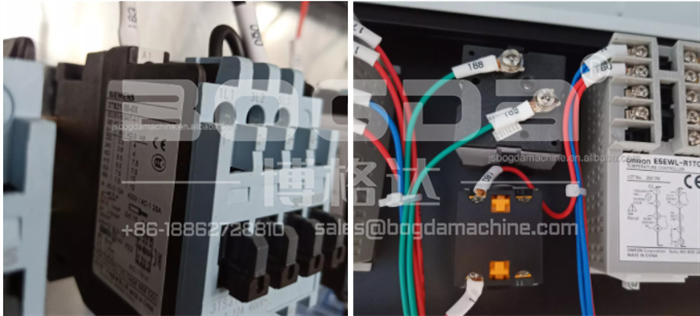

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

PVC Ceiling Panel Making Machine with Online Printing / PVC Ceiling Machine

PVC Ceiling Panel Making Machine with Online Printing / PVC Ceiling Machine  BOGDA PVC WPC floor skirting board foam baseboard extruder PVC profile extruder machine

BOGDA PVC WPC floor skirting board foam baseboard extruder PVC profile extruder machine  SJ25 Single Screw Small Plastic Co-extruder Lab Small Test Extruder

SJ25 Single Screw Small Plastic Co-extruder Lab Small Test Extruder  Plastic PP PE PPR PC ASA Pipe / Profile Single Screw Extruder Lab Extruder

Plastic PP PE PPR PC ASA Pipe / Profile Single Screw Extruder Lab Extruder Copyright © Bogda Machinery Group All Rights Reserved | Sitemap