1. Capacity: 120-150KG/H 2. Extrusion speed: 3-5m/min 3. Main motor: SIMO brand 4. Inverter: ABB or Huichuang brand 5. Raw material: pvc powder

Finished Product

Application of PVC Floor Plinth PVC Foamed Skirting PVC Skirting Baseboard

Plastic skirting boards, architraves and trims are a popular alternative to traditional wooden skirting. The plastic skirting boards, architraves and trim are available in either a plain white or a light oak wood effect, to blend seamlessly into the home.

Plastic skirting, architrave and trims do not need painting (but can be if you like), they do not swell with water spillages, do

not warp, or split or suffer from woodworm unlike the wooden alternative.

Specification

| NO. | PVC skirting baseboard extrusion line List |

| 1 | Screw Loader |

| 2 | SJSZ55 Conical Double Screw Extruder with or without Co-extruder |

| 3 | Calibration Cooling Table for PVC Skirting Board Plinth |

| 4 | Haul-off Machine for PVC Skirting Board Plinth |

| 5 | Cutting Machine for PVC Skirting Board Plinth |

| 6 | Stacker for PVC Skirting Board Plinth |

| 7 | Oil Printing Machine or Hot Stamping Machine or Laminating Machine |

Product Description

SJSZ55/110 Conical twin screw extruder for plinth for floor skirting

1. Capacity: 120-150KG/H

2. Extrusion speed: 3-5m/min

3. Main motor: SIMO brand

4. Inverter: ABB or Huichuang brand

5. Raw material: pvc powder

Extrusion mould for pvc plinth

1. Material: 3Cr17

2. Cap with bottom extrusion together

3. Customized according to drawing

Vacuum calibrator and Water cooling tank

3 meters water tank

Stainless steel material water cooling tank

Surface treatment for BOGDA Plastic Profiles PVC Foamed Skirting Board Extrusion

Hot stamping machine for pvc foamed skirting baseboard. We can customize kinds of decorative pattern on the surface.

The design of the machine is entirely up to you.

Haul-off machine for BOGDA Plastic Profiles PVC Foamed Skirting Board Extrusion

Pulling Size: 200mm width

Motor Power:3KW

Total Length: 1800mm

Effective Length: 1500mm

Control Method: Frequency Conversion

Saw cutting machine for BOGDA Plastic Profiles PVC Foamed Skirting Board Extrusion

PLC control

Stacker for plastic profiles

Stack Length: 3500mm

Material: Stainless steel

Working Method: Automatically

Clamping Type: Skirting Structure

PVC Floor Baseboard/ PVC Skirting Board/ PVC Floor Plinth Skirting

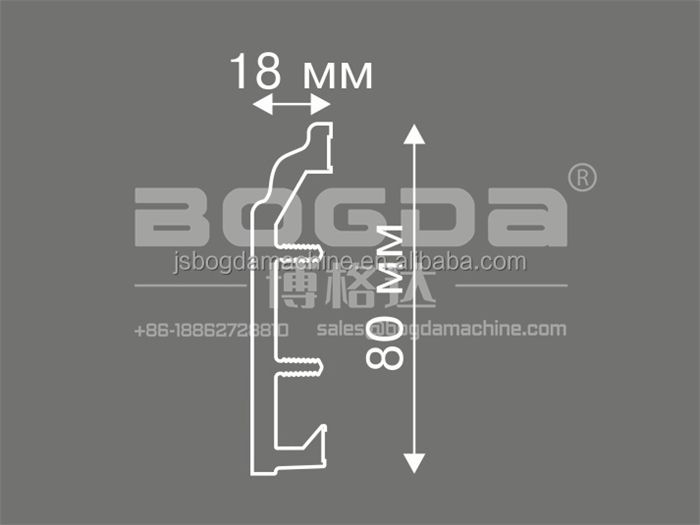

Customized pvc skirting size

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap