PVC Wall Panel Machine adopts special designed SJSZ65/132 conical twin screw extruder, this extrusion line include screw feeder, host extruder, extrusion mold, vacuum calibrating tank, haul-off machine, PVC wall panel cutter and stacker.

PVC wall panel description

PVC Wall Panel Machine adopts special designed SJSZ65/132 conical twin screw extruder, this extrusion line include screw feeder, host extruder, extrusion mold, vacuum calibrating tank, haul-off machine, PVC wall panel cutter and stacker.

Features of PVC extruder machine

1- Speed controlled by inverter, saving power and easy to adjust speed

2- Extruder temperature controlled by Omron intelligent controller, temperature fluctuation self adjusting

3- Low power consumption, lowest total production line consumption 25kw/h

4- Economical price, suitable for large scale investment

Finished products-application of PVC wall panel

Normal PVC wall panel is 300mm, 400mm, 600mm width, with different section shape and height, the surface of PVC wall panel can be treated by double color printing & UV coating, or by heat transfer printing, or by lamination, which make marble and wooden design on surface of product.

PVC wall panels application for indoor decorations

Machine List

SJZ65/132 conical twin screw extruder- PVC wall panel extrude machine

1- Gearbox running stable, low noise, long service time, with nice outline

2- Extruder barrel control system use cast aluminum heaters, wind cooling system, precision temperature control

3- SIEMENS electric element, well known quality, guaratee machine's operate

Technical parameter

| Model | SJZ51/105 | SJSZ65/132 | SJZ80/156 |

| Scew diameter | 51/105 | 65/132 | 80/156 |

| Mian motor power | 22 | 37 | 55 |

| Capacity(kg/h) | 110-150 | 220-260 | 320-380 |

| Effective length of screw(mm) | 1050 | 1430 | 1800 |

| Barrel heating power(kw) | 18.5 | 37 | 55 |

| Brand | BEIDE/DELIXI/TECO | ||

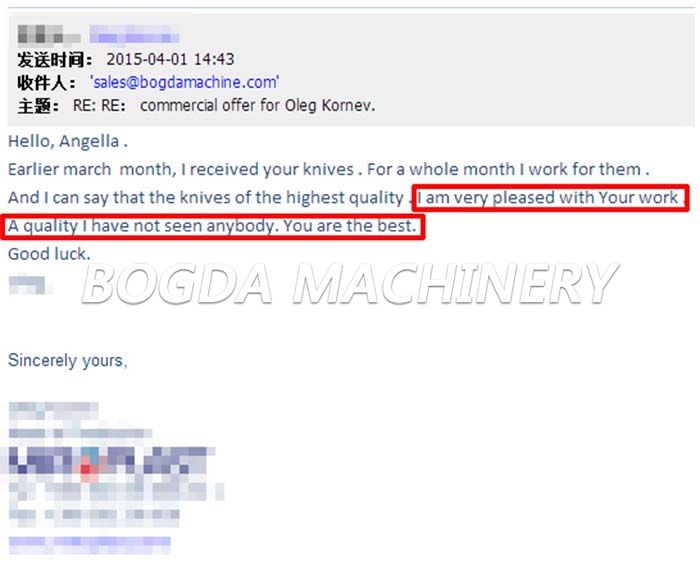

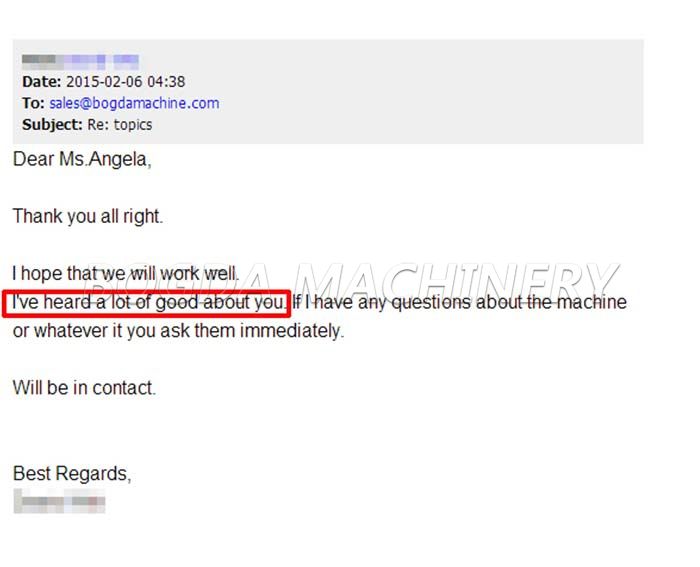

Customer Feedback

BOGDA International Co, BOGDA Machinery Co, who is a leader of Plastic Machine and Raw Material. Such as Plastic Profile/Pipe/Sheet Extrution Equipment,Injection Machine and Waste PP/PE Film, PET Bottle Washing Recyce Machine, as well as Plastic Granulating Line, meanwhile we are familiar with kinds of raw material to help our customers choose the most suitable machine on best quality by economically.

In wooden cases, wooden splints, wrap film and other specialized packaging film, to ensure that the machine impact damage in the long time of land and sea transport, thus reaching the customer factory intact.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap