Extrusion speed:1-6m/min Voltage:380V, 220V,380V,440V Temperature control: electric

Extrusion speed:1-6m/min

Voltage:380V, 220V,380V,440V

Temperature control: electric

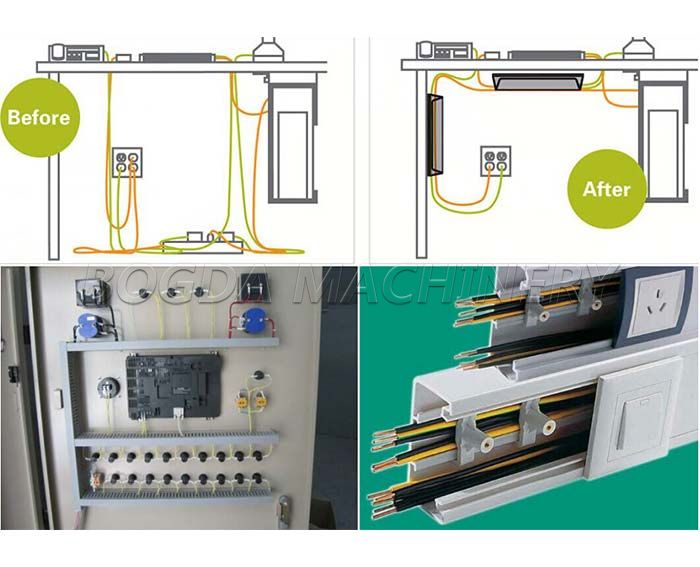

PVC electrical channel extrusion description

1.PVC cable trunk extrusion line is applied to produce U channel profile which used as PVC electrical cable trunking/cable duct.

2.This production is composed of conical twin-screw extruder, vacuum calibration table, haul-off, cutter and stacker.

3.Chang different extruding mould,this machine can also produce PVC door & window profiles, foamed special shaped materials profiles, decoration plate material, profile and multi-hole wire plastic products, etc.

Extrusion process

PVC powder + additives → Mixer → Screw feeder → Extruder → Mould → Vacuum forming table→ Haul-off machine→ Cutting machine → Stacker

Machine List

PVC electric cable trunking extrusion line include forced feeder, conical twin screw extruder, mould, vacuum calibration & cooling table, haul off machine, stacker, punching machine. Usually we choose SJSZ55/110 as mian extruder.

Extruder+2 cavities mould:for small size cable trunkings (12*12,16*16,etc)

Technical parameter

PVC electric cable trunking sizes

| 15×10 | 16×16 | 16×25 | 20×10 | 20×20 | 25×16 | 25×25 | |

| 30×12 | 30×25 | 30×30 | 35×40 | 35×60 | 35×75 | ||

| 40×16 | 40×25 | 40×30 | 40×40 | 40×60 | 40×60 | 40×80 | |

| 45×25 | 45×30 | 45×45 | 45×60 | 45×90 | 45×90 | ||

| 50×30 | 50×40 | 50×50 | 60×25 | 60×60 | 60×60 | 65×45 | 75×75 |

| 80×40 | 80×60 | 80×80 | 90×40 | 90×75 | 90×75 | 90×90 | |

| 100×25 | 100×40 | 100×60 | 100×100 | 120×80 | 120×80 | 120×100 |

BOGDA International Co, BOGDA Machinery Co, who is a leader of Plastic Machine and Raw Material. Such as Plastic Profile/Pipe/Sheet Extrution Equipment,Injection Machine and Waste PP/PE Film, PET Bottle Washing Recyce Machine, as well as Plastic Granulating Line, meanwhile we are familiar with kinds of raw material to help our customers choose the most suitable machine on best quality by economically.

In wooden cases, wooden splints, wrap film and other specialized packaging film, to ensure that the machine impact damage in the long time of land and sea transport, thus reaching the customer factory intact

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap