The XPS line production line is designed to extrude polystyrene foam profile materials through the principle of hot extrusion. The main feature of this process is the continuous mixing of the foaming agent in the mixture. The various components prepared in the mixer continuously feed the mixture into the extruder

Production Application

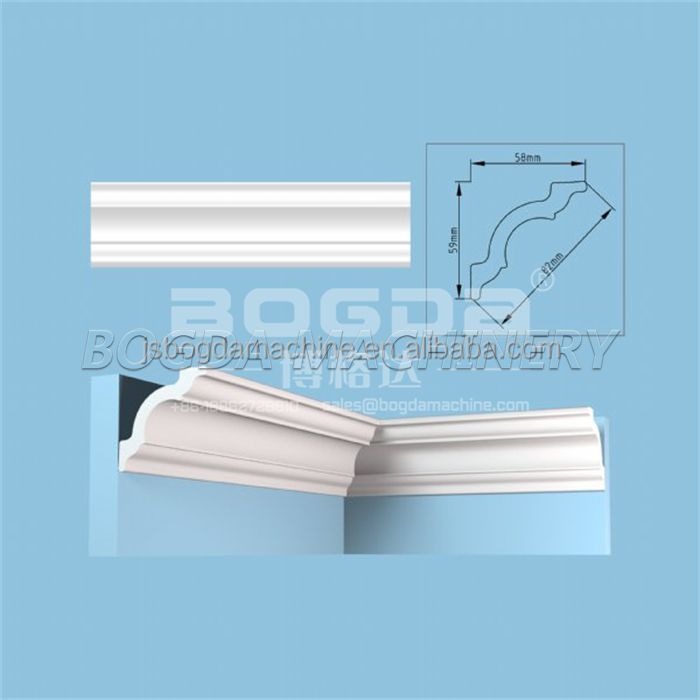

XPS decorative lines, produced by XPS foaming technology, have many advantages such as high surface gloss, smooth and delicate, light material, waterproof, mothproof, mildew proof, no deformation, no cracking, no falling off and so on.

XPS decorative lines are widely used in interior decoration of home improvement, hotels, villas, and various professional laboratories. Its flexible appearance and colors that can be changed according to customer needs bring a perfect improvement of the decoration effect.

XPS decorative lines overcome the shortcomings of traditional decorative material styles such as GRC lines, plaster, marble, wood, PVC wood plastic lines, single color and shape, and complex installation. The structure is diverse, the lines are smooth and beautiful, the installation is simple and convenient, green and environmentally friendly, and 100% of the materials can be recycled.

Machine Specification

BOGDA PS GPPS XPS Polystyrene Extruder, XPS Foamed Profiles Production Machine Line

The XPS line production line is designed to extrude polystyrene foam profile materials through the principle of hot extrusion. The main feature of this process is the continuous mixing of the foaming agent in the mixture. The various components prepared in the mixer continuously feed the mixture into the extruder through a pneumatic quantitative device. The mixture is heated in the extruder to reach the melting point of polystyrene. . The mixture and the foaming agent are fully mixed and then extruded through the die to produce various shapes of XPS decorative lines.

Product Paramenters

| BOGDA XPS Polystyrene Extruder, XPS Foamed Profiles Production Machine Line | ||

| Model | Model 1000 | Model 2000 |

| Raw material | XPS GPPS | XPS GPPS |

| Capacity | 500-1200kg/day | 500-2000kg/day |

| Product thickness | 4-12mm | 4-15mm |

| Product width | 20-120mm | 50-160mm |

| product density | 50-100kg/m³ | 50-100kg/m³ |

| Cooling method | water cooling/fan cooling | water cooling/fan cooling |

| Total power | 60kw | 100kw |

| Install dimension | 25x4.5x3.2m | 28x4.5x3.2m |

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap