WPC extrusion machine / PVC wall panel production line / WPC profile extruder making machine can be discussed based on different materials, it is a kind of high efficiency equipment for plastic extrusion, it is mainly composed by force feeder, soft plasticization screw and barrel, high precision gearbox, exhaust system.

Product Description

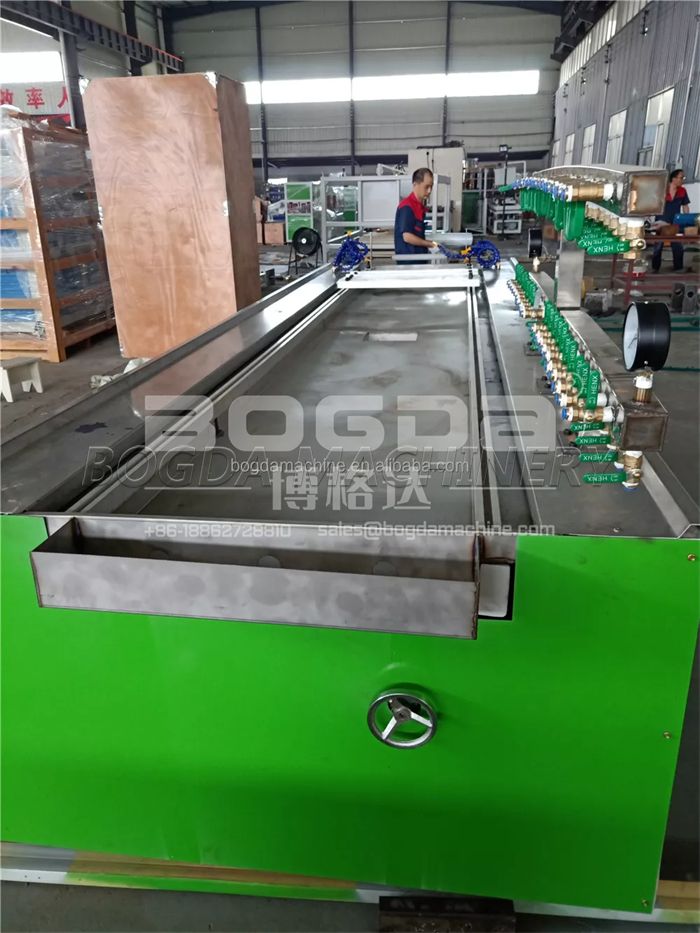

WPC extrusion machine / PVC wall panel production line / WPC profile extruder making machine can be discussed based on different materials, it is a kind of high efficiency equipment for plastic extrusion, it is mainly composed by force feeder, soft plasticization screw and barrel, high precision gearbox, exhaust system, it is features of even mixing, better plasticization,stable working, high capacity, and it is suitable for produce PVC products from mixed powder, within different mold and other auxiliary equipments, it can produce plastic pipe, profile, board, sheet, granules and so on.

Extrusion Products

Extrudered Wall Panels appalication in kinds of fields

Extruder Details

SJZ Series Conical Twin Screw Extruder Machine - PVC WPC wall panel extrusion making machine plant.

2.Gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long service time.

3.Extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

3.Extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

4.Screw and barrel: screw core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

4.Screw and barrel: screw core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

5. Siemens Electrical Element: our machine choose high quality material for producing each details. SIEMENS elementsis well-know greatest quality, guarantee machine's operate.

Technical Parameter

1. PVC wall panel extrusion machine is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produced all sorts of PVC plastic, profile, plate material, sheet material, bar material and granulation.

2. PVC extrusion for plastic ceiling panel have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. Ceiling Panel and wall panel extruder plant system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plastic city performance and material quality

4. Plastic Extruder machine for Wall panel is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box on Walling Panel making machine is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear large extruding pressure.

6. Plastic extrusion for PVC wall panl and ceiling panel electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.

| Model | SJZ45 | SJZ51 | SJZ65 | SJZ80 | SJZ92 |

| Screw diameter (mm) | 45/100 | 51/105 | 65/132 | 80/156 | 92/188 |

| Screw rotation speed (r/min) | 4-45.5 | 1-30 | 1-34.7 | 1-36.9 | 1-32.9 |

| Effective length of screw (mm) | 1000 | 1050 | 1430 | 1800 | 2520 |

| Main motor power (kw) | 15 | 22 | 37 | 55 | 90 |

| Barrel heating power (kw) | 12 | 18 | 24 | 36 | 48 |

| Capacity (kg/h) | 95 | 110 | 250 | 380 | 520 |

| Central height (mm) | 1000 | ||||

| Net Weight(kg) | 3000 | 3200 | 5000 | 6500 | 7500 |

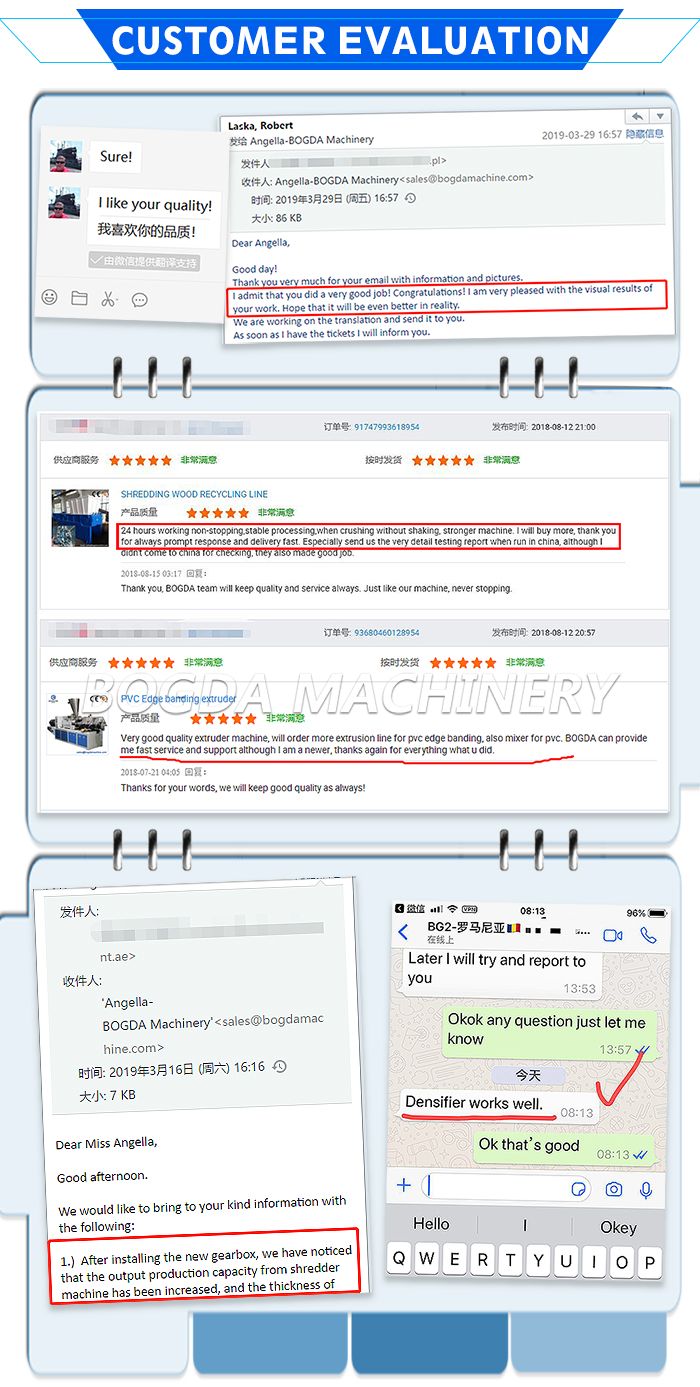

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap