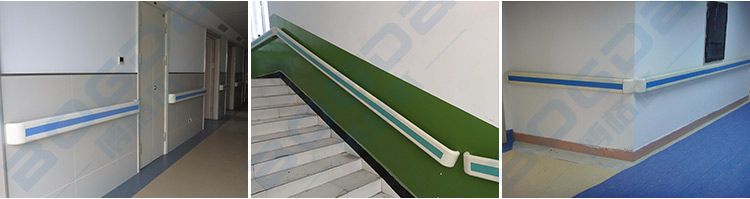

1. The surface material for antibacterial PVC, ABS material, anti-corrosion, fire, antibacterial, easy to clean. 2. High quality aluminum alloy lining, reasonable fastening, anti-collision resistance 3. It is more convenient for patients and the elderly to walk. 4. Simple installation, convenient maintenance, durable. 5. Diversified colors match

Production Application

PVC Protective Armrest Hospital Corridor Handrails Profiles Extrusion Line

The anti-collision handrail of hospital corridor is composed of high quality aluminum alloy base material, high polymer anti-bacterial PVC plastic cover plate, ABS resin elbow, ABS resin base seat, expansion gong bolt and small gong wire. The crash-proof handrail can be installed in hospitals, nursing homes, welfare homes, clubs for the elderly, activity centers for the disabled and other public places to help patients and the elderly walk.

1. The surface material for antibacterial PVC, ABS material, anti-corrosion, fire, antibacterial, easy to clean. 2. High quality aluminum alloy lining, reasonable fastening, anti-collision resistance 3. It is more convenient for patients and the elderly to walk. 4. Simple installation, convenient maintenance, durable, 5. Diversified colors match the overall decoration style.

Product Description

PVC Protective Armrest Hospital Corridor Handrails Profiles Extrusion Line

| PVC Protective Armrest Hospital Corridor Handrails Profiles Extrusion Line | ||

| 1 | 300/600L High Speed Heating and Cooling Plastic Mixer Unit | According to your demand |

| 2 | SJSZ55/120 twin screw extruder | With Spring Loader |

| 3 | SJ30/25 co-extruder | |

| 4 | Extrusion mould | whole set |

| 5 | Embossing and laminating machine | |

| 6 | Vacuum calibration machine | |

| 7 | Haul-off machine | |

| 8 | Cutting machine | |

| 9 | Stacker | |

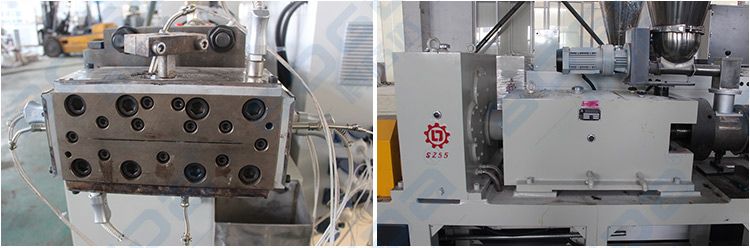

SJSZ55/120 twin screw extruder with full automatic spring loader. Stable for plasticizing effect.

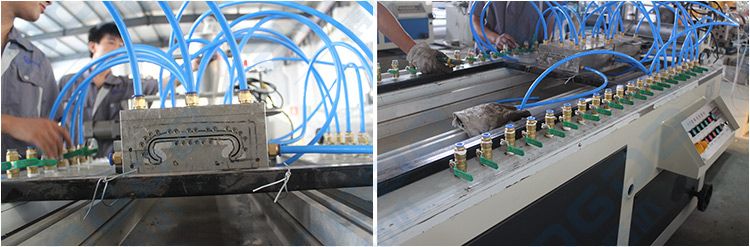

Adopt special extrusion die for medical handrail, using high quality heat stabilized die steel.

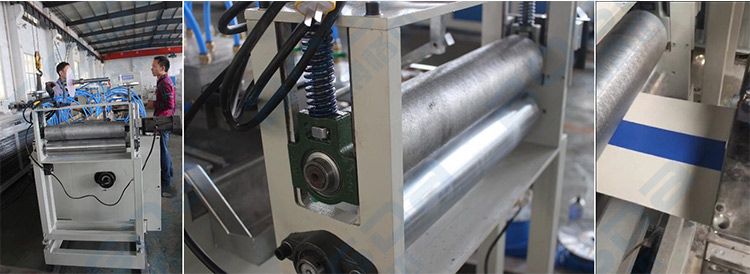

Embossing and laminating machine unit

1. Vacuum setting table: vacuum setting table for multi-channel water cooling and multi-channel vacuum. 2.Vacuum setting die can make high forming precision, high cooling efficiency. 3. The lengthened setting platform ensures the high stability of the whole production process.

Custom-made crawler tractor: more stable traction, less fluctuation. Dual servo motor drive, stable power.

Saw blade cutting machine: the use of large bar, special profile saw blade cutting machine, cutting fast, one step in place, the incision of neat and beautiful.

Full automatic stainless steel stacker for pvc profiles

Product Paramenters

| Model | SJSZ55/120 |

| Product Width (mm) | 140mm |

| Product Thickness (mm) | 1.7mm |

| Total Motor Power (kw) | 110 |

| Extruder Max. Capacity (kg/h) | 100-120kg/h |

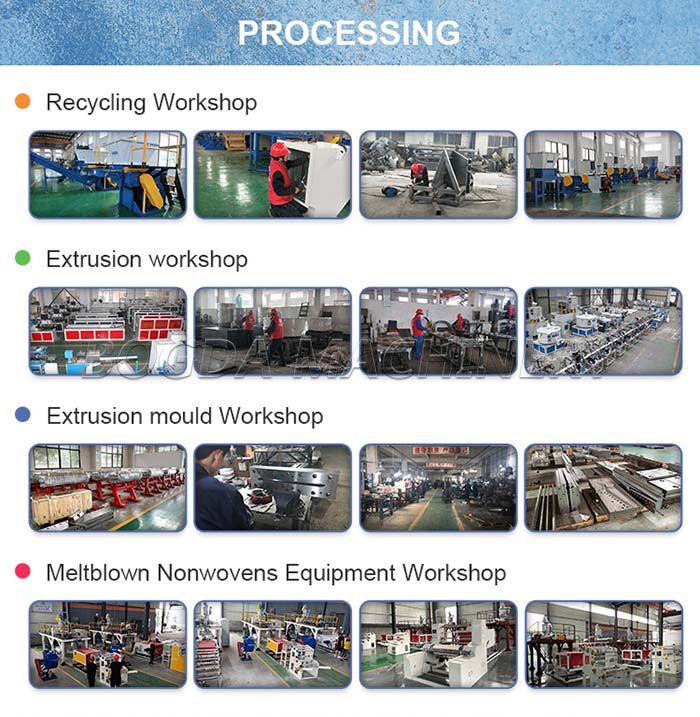

BOGDA Machinery Group is located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap