Features of BOGDA WPC Lumber Decking Profile Extruder Make Machine (1). High recyclable, eco-friendly, saving forest resources. (2). With the look of the natural wood but less timber problems. (3). Moisture/water resistant, less rotten, proven under salt water condition. (4). Barefoot friendly, anti-slip, less cracking, less warping.

Product Description

BOGDA WPC Lumber Decking Profile Extruder Make Machine

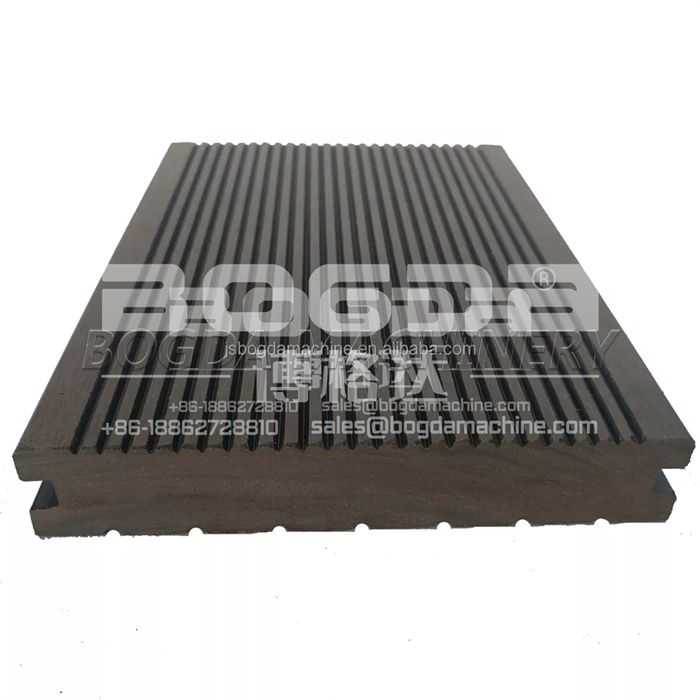

Composite outdoor decking is preferred for city construction and layout, such as parks, swimming pools, paths, marina docks and so on. anti-slip, anti-oxidation, minimal moisture absorption, termite resistance, etc.

Features of BOGDA WPC Lumber Decking Profile Extruder Make Machine

(1). High recyclable, eco-friendly, saving forest resources. (2). With the look of the natural wood but less timber problems. (3). Moisture/water resistant, less rotten, proven under salt water condition. (4). Barefoot friendly, anti-slip, less cracking, less warping. (5). Requires no painting, no glue, low maintenance. (6). Weather resistant, suitable from minus -40 to 60 centigrade degree. (7). Well done of termites, insects, and moldy-proof. (8). Available in different colors. (9). Easy to install and clean, low labor cost.

Specification

BOGDA WPC Lumber Decking Profile Extruder Make Machine

This WPC machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc.

Wood plastic composite machine, PE wood composite machine. WPC outdoor floor machine. WPC production line PP/PE WPC Profile Production Line can continuously produce PP/PE WPC profile.

The WPC profile adopts two-step production process:

The first step is using WPC granulating machine to make WPC pellets from recycled PP/PE material,wood powder and chemical additives.The max wood percentage can be 70%.

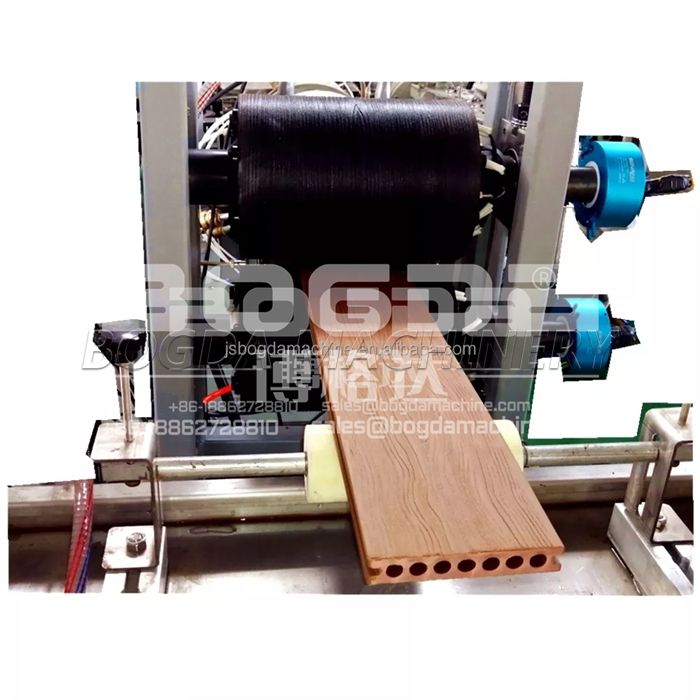

The WPC profiles extrusion line will make the WPC pellets into WPC profiles by equip customized mold.We can equip on-line embossing machine to achieve 3D wooden pattern.

WPC deck floor tile machine WPC profiles extrusion line WPC profile production line WPC outdoor deck machine

The profiles produced by this production line can be sanded and brushed by sanding machine and brushing machine.

Mould for BOGDA WPC Lumber Decking Profile Extruder Make Machine

After adding additives, high-speed mixing, granulation is carried out, and then the pellets are extruded into a molding material by an extruder.

| 1 | Mixing Machine for Raw Material |

| 2 | Wood-plastic WPC Parallel Twin Screw Granulating Machine |

| 3 | SJZ65/132 Conical Double Screw Extrusion Line |

| 4 | Brushing Machine/ Sanding Machine |

Main Extruder for BOGDA WPC Lumber Decking Profile Extruder Make Machine

6m Length Calibration Cooling Tank for BOGDA Small WPC Fencing Extruder Making Machine

Embossing Device for BOGDA WPC Lumber Decking Profile Extruder Make Machine

The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

BOGDA Small WPC Fencing Extruder Making Machine

This type of floor can be used in gardens and villas. Wait for the outdoor platform. Wood-plastic composite board is a kind of wood (wood cellulose, plant cellulose) as the basic material, thermoplastic polymer materials (plastics) and processing aids, etc., mixed uniformly and then heated and extruded by mold equipment. The high-tech green and environmentally friendly materials, combined with the performance and characteristics of wood and plastic, are new environmentally friendly high-tech materials that can replace wood and plastic. The English abbreviation of Wood Plastic Composites is WPC.

BOGDA Machinery Technology Co., Ltd is a leader of plastic machine and raw material, such as plastic profile/pipe/sheet/board extrusion equipment, waste PP/PE film/PET bottle washing recycling machine,recyclying production line, as well as plastic granulating line. Meanwhile, we are familiar with kinds of raw materials to help you choose the most suitable machine on best quality by economically.

BOGDA has different production factory and strong technical departments to study each customer's requirements until meeting final order. Serious sales and after-sale department to reply inquiry and solve problems for custom in 24 hours, which already exported machine and materials to Russia, Venezuela, Kazakhstan, Turkey, Brazil, Dubai, Philippine, Malaysia, Thailand, Vietnam, Poland, India and so on.

Fast response, good quality, best price and perfect service are our advantages and culture.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap