Extrusion equipment for biodegradable polylactic acid environmental packaging board,Extrusion equipment for biodegradable polylactic acid environmental packaging board,Bogda make Extrusion equipment for biodegradable polylactic acid environmental packaging board made in china

Production Application

What is PLA ?

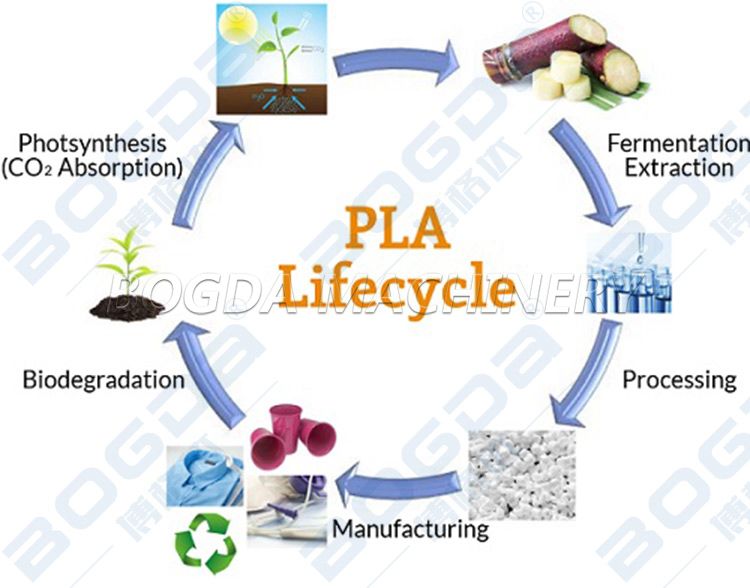

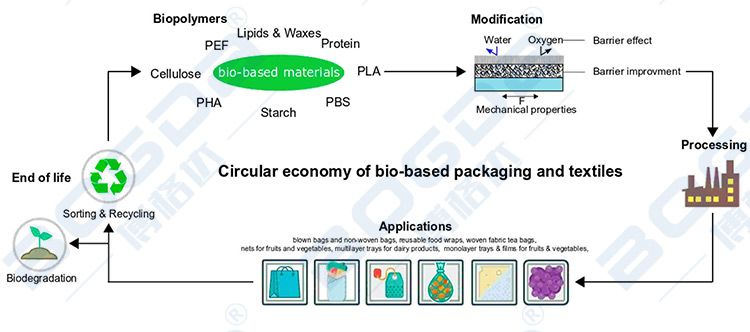

Polylactic acid.It is a new bio-based and renewable biodegradable material, which is made of starch from renewable plant resources (such as corn, cassava, etc.).The starch raw material is saccharized to get glucose, and then the glucose and certain strains are fermented to produce high purity lactic acid, and then the polylactic acid with certain molecular weight is synthesized by chemical synthesis method.

It can be used in the production of PET and PLA sheets, reduce the energy consumption of pre-crystallization drying, and adapt to the production of secondary materials. It has the characteristics of high yield, low energy consumption and excellent plasticization. The screw is a building block structure with multiple combinations, and has a wide range of applications. It is not only suitable for the production of PET, but also suitable for PLA biodegradable materials and starch-based degradable materials.

Product Description

Uses: Excellent processability, transparency, barrier, non-toxic, odorless, pollution-free, easy to recycle and other

characteristics.

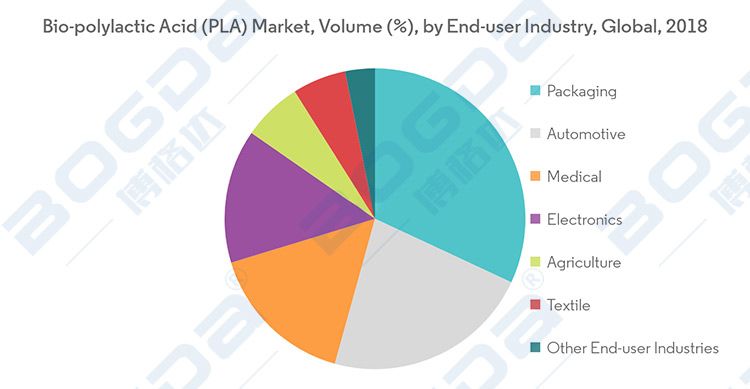

Vacuum forming: food packaging, toy boxes, stationery boxes, gift boxes, hand tools and hardware packaging.

Barrier Use: Electronic Parts Packaging.

General use: foldUses: Excellent processability, transparency, barrier, non-toxic, odorless, pollution-free, easy to recycle and other

characteristics.

Vacuum forming: food packaging, toy boxes, stationery boxes, gift boxes, hand tools and hardware packaging.

Barrier Use: Electronic Parts Packaging.

General use: folding, garment collar, decorative materials, folders, document covers.

Special uses: medical equipment, pharmaceutical packaging, industrial anti-corrosion protection, microwave oven baking tray.

ing, garment collar, decorative materials, folders, document covers.

Special uses: medical equipment, pharmaceutical packaging, industrial anti-corrosion protection, microwave oven baking tray.

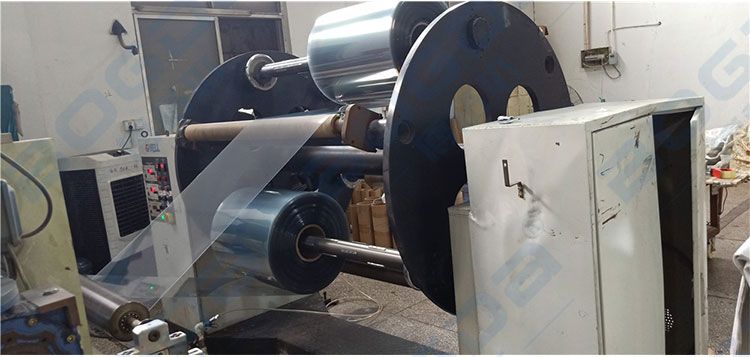

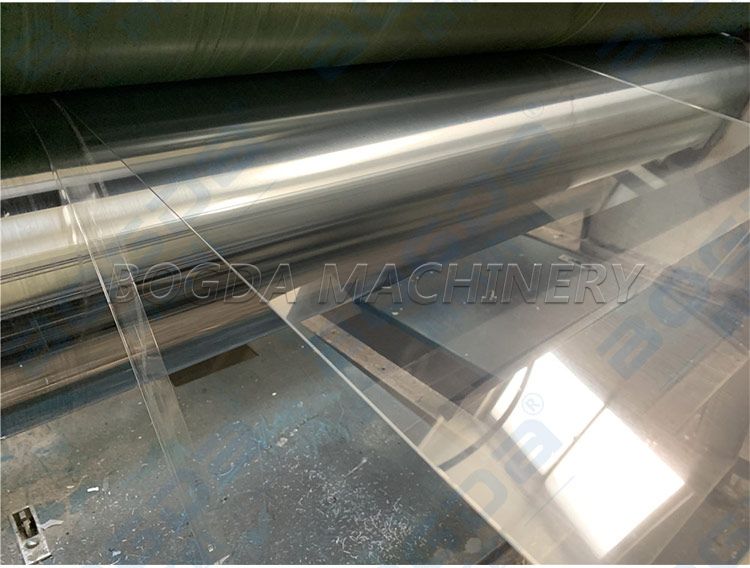

PLA/PET environmental protection packaging sheet extrusion production line is mainly composed of flat double extruder, mesh changer, metering pump, die, three rollers, cooling bracket, traction, winding and so on. The new type of co-directional double-sided extruder has the characteristics of low energy consumption, simple process and easy maintenance of equipment. Its unique screw combination structure minimizes the viscosity drop of PET resin. The symmetrical thin-walled roller improves the cooling efficiency and productivity as well as the quality of sheets. The multi-component feeding device can reasonably control the proportion of new materials, recycling materials, masterbatch and so on. The sheets produced can be used in the fields of plastic absorption printing and packaging. The electric system adopts Siemens subsystem, which is characterized by simple operation, high automation and cost saving.

The extruder is equipped with a melt metering pump with a constant voltage output and a closed-loop automatic control of pressure and speed.

The whole machine adopts PLC control to realize automatic control of parameter setting, data operation, feedback and alarm functions.

New non-drying PET three-exhaust extrusion production line (no need for crystallization dehumidification drying system) is a high-quality PET and PLA sheet unit developed by the company. Its production process is simple, energy consumption is low, and production cost is greatly reduced.

PLA resin is suitable for processing on traditional pet extrusion molding machine. The thickness of the recommended sheet is within the range of 0.2-1.0mm. General mechanical requirements: ordinary screw, length-diameter ratio from 24:1 to 32 : 1, it is recommended to use a smooth bucket. After drying, the raw materials are stable in the melting state. Pla resin revode101, unlike other series of resins, is subject to the following special treatment methods:

1. Use low viscosity polystyrene or polypropylene cleaning extruder to keep the temperature in a stable state.

2. Make sure the air humidity in the feeding bucket is below dew point-40 ℃ and avoid dust pollution.

3. Under the above conditions, pla resin was poured into the extruder.

4. Adjust the temperature of the equipment to the processing temperature of pla resin.

5. When off, use a low viscosity polystyrene or polypropylene cleaning machine.

Note:

1. Before adding polylactic acid, it is important to ensure that the drying system and transportation system are clean, because if there are other materials that can not be melted at pla processing temperature, it will cause the blockage of the filter and affect the normal production.

2. If you use a polypropylene cleaning machine, you cannot use hot cross-linked polypropylene. The common feed throat cooled by extrusion sheet can be used to extrude pla sheet by single screw extruder with ratio of length to diameter from 24:1 to 36:1. It is suggested that melt pump or static mixer should be added to the die head to ensure the stable transportation of the material. At the same time, in order to ensure melt quality and improve productivity, mesh changers should also be installed.

Specification

| Model | Designed extrusion output (kg/h) | Product Width (mm) | Product Thickness (mm) | Color |

| SJ120/65 | 200-1000kg/h | 600-1500 | 0.18-2mm | black+yellow |

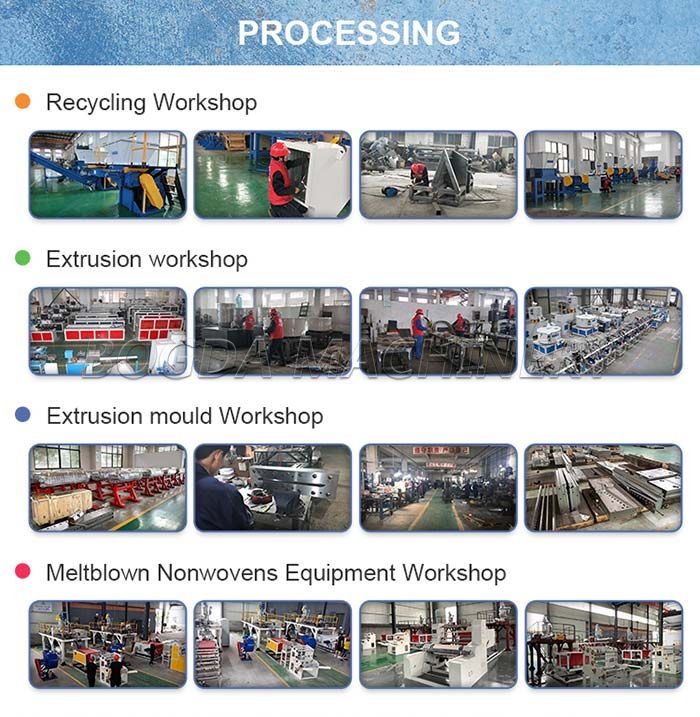

BOGDA Machinery Group is located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

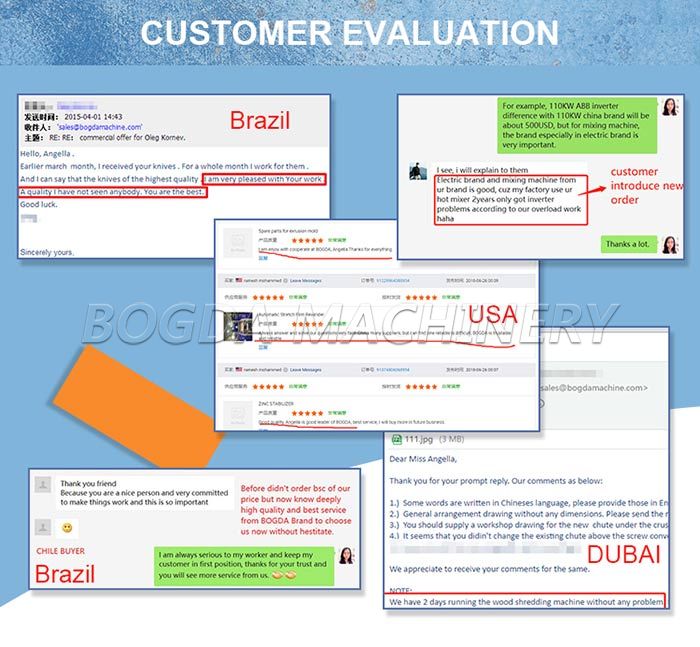

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap