PVC sheet extruder machine Motor: SIEMENS motor PVC panel extruder machine Inverter: ABB Inverter Key word: PVC Artificial Marble Sheet Extrusion line PVC board extrusion line Heating method:Foundry Aluminum Heater PVC sheet extruder machine Contactor:Shneider contactor PVC sheet extruding lineCooling method: Recycling water

Description

1. Plastic Sheet Production Line screw adopt the design special mixing material function and high plasticization capacity. This guarantee the uniformity of plastic melting, coloring and high discharge.

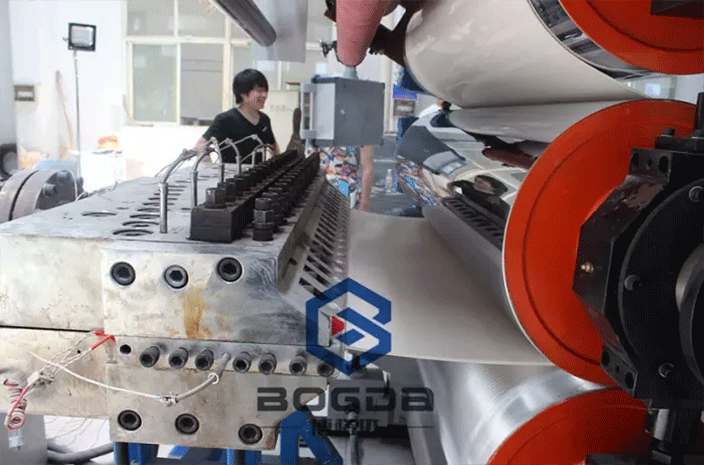

2. Plastic Sheet Production Line Mold head adopts throttling design(Cloths rack type), which make more precision of adjusting the thickness of sheet.

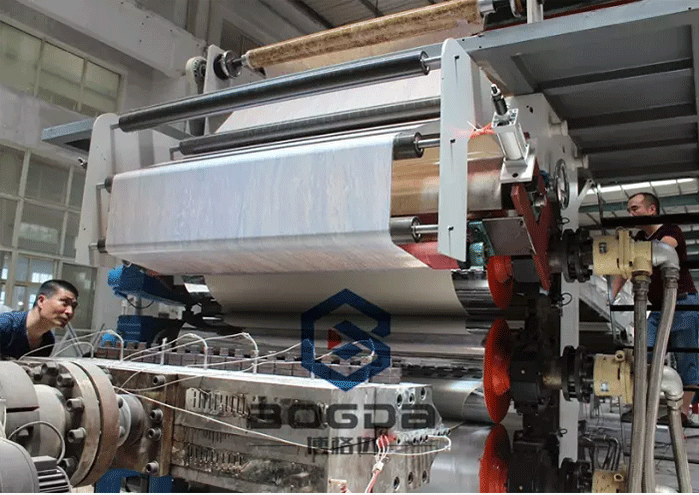

3. Plastic Sheet Production Line ±1℃ precision degree of temperature control, can control the plasticization process, thickness and surface smooth of sheet accurately.

4. Plastic Sheet Production Line arrange of roller can be vertical, horizontal of free adjusting type, which can give more selection basing on different thickness of sheet.

5. Plastic Sheet Production Line screw adjusting and oil pressure press-roller double direction adjusting can control the thickness of sheet accurately.

6. Plastic Sheet Production Line double loop cooling system and mold temperature controller are adopted to control pre-roller temperature, by which sheet thickness can be controlled accurately.

7. Plastic Sheet Production Line cutting machine can cut the sheet to get accurate length (2400mm).

8.Plastic Sheet Production Line winder adopt high torque motor, which cooperating with four shafts automatic strain control can adjust the winding speed and winding strain to obtain smooth winding. The slitting device can cut sheet free width.

9. Plastic Sheet Production Line automatic measuring meter instrument can set sheet length.

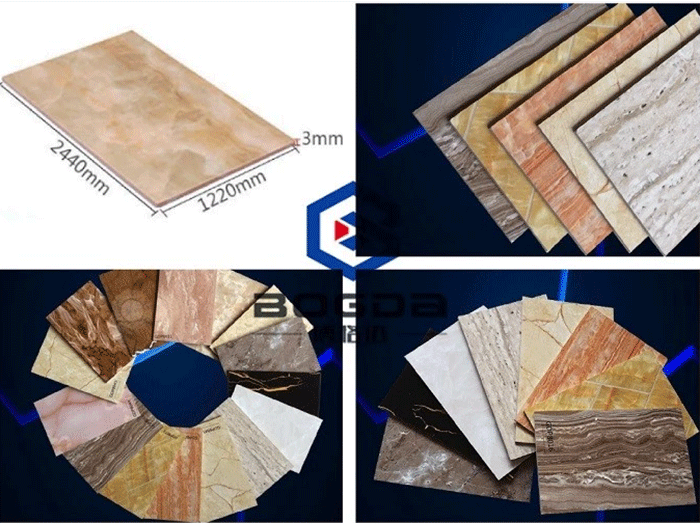

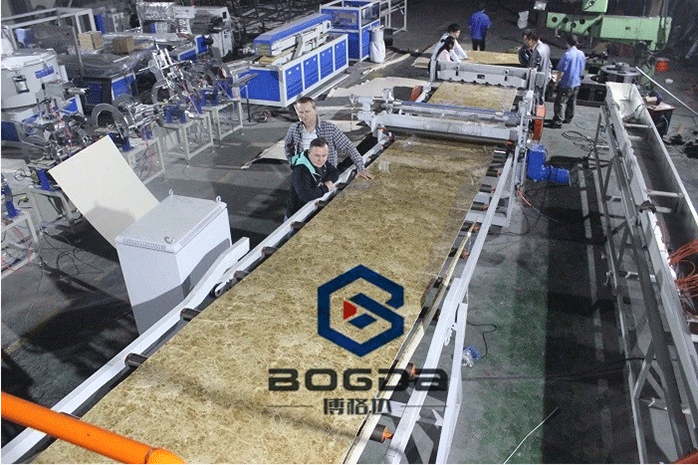

Extrusion products

Plastic Sheet Production Line

(Width: 1220mm * Length: 2440mm * Thickness: 3-8mm

Application

Plastic Sheet Production Line with the advantage of environmental protection, light weight, easy maintenance, no radiation, cheap price, popular decoration use in KTV, Hotel, Leisure facility, Home decoration, Hall, Meeting room, etc.

Our company have advance & rich experience in technology and skills, design and produce in Artificial Marble PVC Decoration Sheet Extruder Machine Line.

Extrusion Flow

Plastic Sheet Production Line: Mixing machine → Material fedding → SJZ-80/156 Conical Twin Screw Extruder Machine → Mold → Three-roller calender (online laminating) → Colling group rollers → Haul off → Transversal Cutter → Edge cutter → Conveyor → UV treatment.

1. Mixing Machine for Plastic Sheet Production Line

Capacity: 650-750kg/h

Paddle material: Stainless steel casting

(Note: Other Auxiliary Machine, such as Crusher, Pulverizer, Mixer, will be provided according to client's requirements)

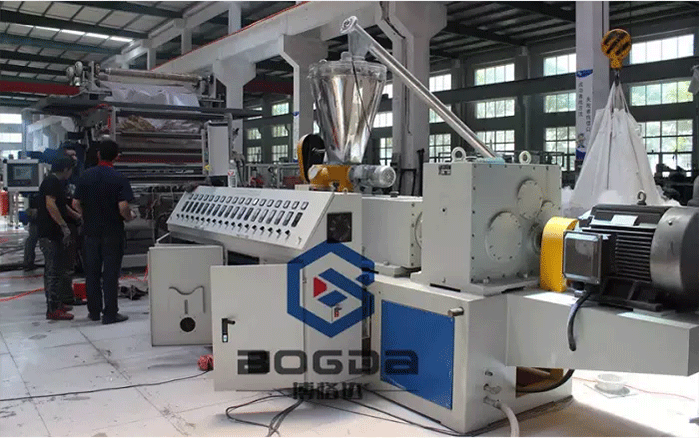

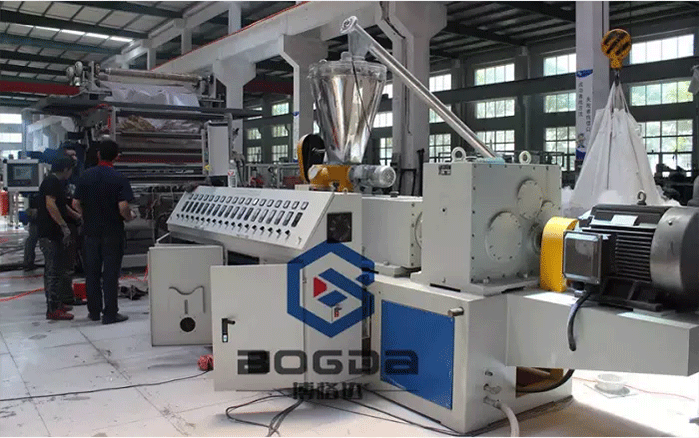

2. SJZ-80/156 Conical Twin-screw Extruder Machine

Screw material: 38CrMoALA

3. Mould - Plastic Sheet Production Line

Material : Germany 2738 steel

4. Three-roller calender - Plastic Sheet Production Line

Unwinding Roller Qty: 2pcs

5. Cooling Stacker & Haul-off - Plastic Sheet Production Line

Cooling Roller Material: Stainless steel

6. Cutting Machine + Stacker - Plastic Sheet Production Line

Knife Material: 9sicr

Technical parameter

1. Plastic Sheet Production Line is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produced all sorts of PVC plastic, profile, plate material, sheet material, bar material and granulation.

2. Plastic Sheet Production Line have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. Plastic Sheet Production Line system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plastic city performance and material quality

4. Plastic Sheet Production Line is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box on PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear large extruding pressure.

6. Plastic Sheet Production Line electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.

| Item | Plastic Sheet Production Line |

| Screw diameter (mm) | 80/156 |

| Screw Qty (pc) | 2 |

| Screw rotation speed (r/min) | 1-36.9 |

| Effective length of screw (mm) | 1800 |

| Main motor power (kw) | 55 |

| Barrel heating power (kw) | 38 |

| Capacity (kg/h) | 320-450 |

| Central height (mm) | 1000 |

| Net Weight(kg) | 6500 |

BOGDA International Co, BOGDA Machinery Co, who is a leader of Plastic Machine and Raw Material. Such as Plastic Profile/Pipe/Sheet Extrution Equipment,Injection Machine and Waste PP/PE Film, PET Bottle Washing Recyce Machine, as well as Plastic Granulating Line, meanwhile we are familiar with kinds of raw material to help our customers choose the most suitable machine on best quality by economically.

In wooden cases, wooden splints, wrap film and other specialized packaging film, to ensure that the machine impact damage in the long time of land and sea transport, thus reaching the customer factory intact

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap