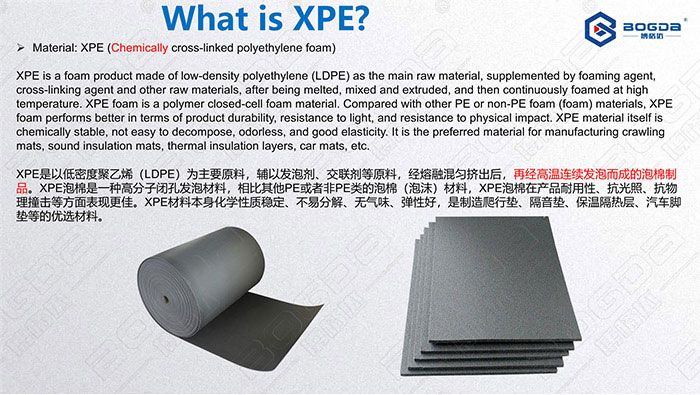

XPE is a foam product made of low-density polyethylene (LDPE)as the main raw material, supplemented by foaming agent,cross-linking agent and other raw materials, after being melted, mixed and extruded, and then continuously foamed at high temperature. XPE material itself is chemically stable, not easy to decompose,odorless, and good elasticity.

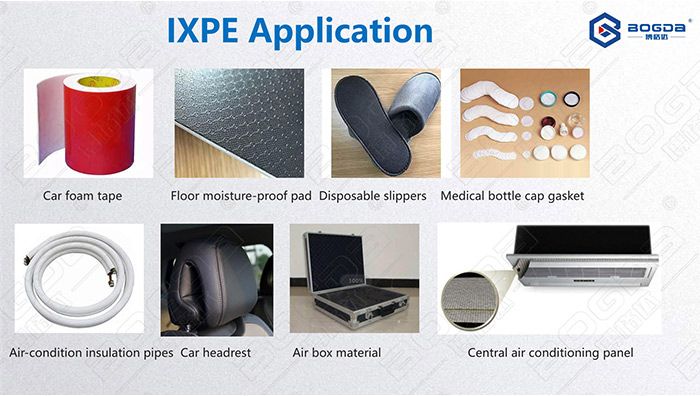

Production Application

Insulation Polyethylene XPE IXPE Cross Linked Foam Roll Sheet Manufacturing Machine

Product Description

Insulation Polyethylene XPE IXPE Cross Linked Foam Roll Sheet Manufacturing Machine

| BOGDA Insulation Polyethylene XPE IXPE Cross Linked Foam Roll Sheet Manufacturing Machine | |||

| IXPE machine | Step 1 | Banbury/Mixing Pelletizing Machine (A,B,C Pellets) | 1 set |

| Step 2 | Mixing+ Extrusion Machine for SHEET | 1 set | |

| Step 3 | High Frequency and High Voltage Electron Accelerator | 1 set | |

| Step 4 | Foaming Furnace (Vertical for IXPE) | 1 set | |

| XPE machine | Step 1 | Banbury Pelletizing Machine (A,B, Pellets) | 1 set |

| Step 2 | Mixing+ Extrusion Machine for SHEET | 1 set | |

| Step 3 | Foaming Furnace (Horizontal for IXPE) | 1 set | |

Banbury/Mixing Pelletizing Machine (A,B,C Pellets):

1) Bnbury/Mixing, 110KW 2) Elevate Transfer 3) Double-screw Feeding for extruder 4) Single Screw Extruder 5) Die-face Hot Cutting Pellet Part 6) Air Cooling System by twice 7) Vibration Sieve 8) Final Storage Hopper

9) Capacity: 80-400KGS/H (depend on formula)

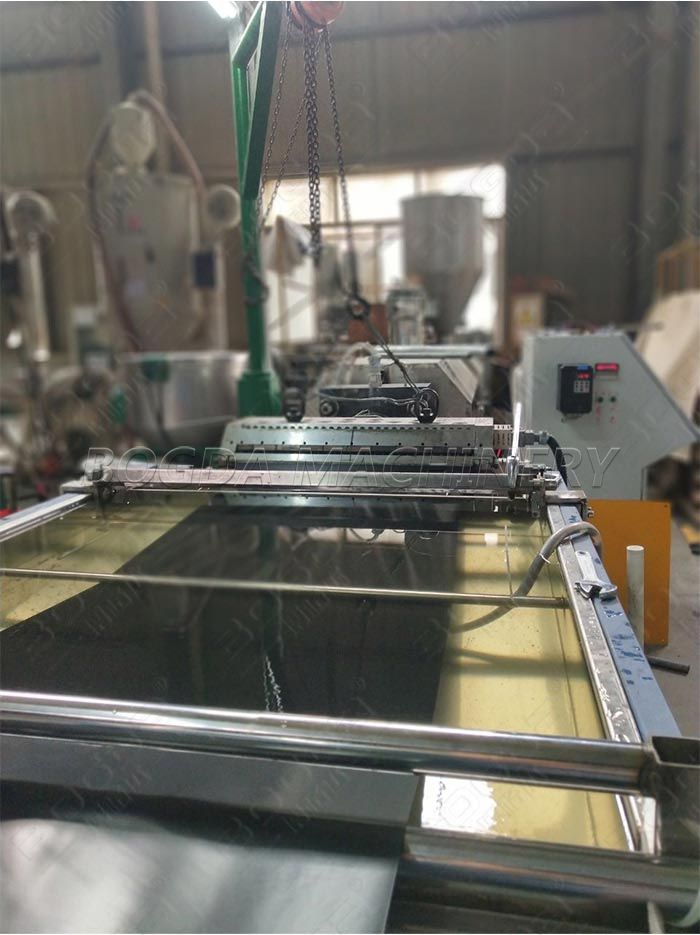

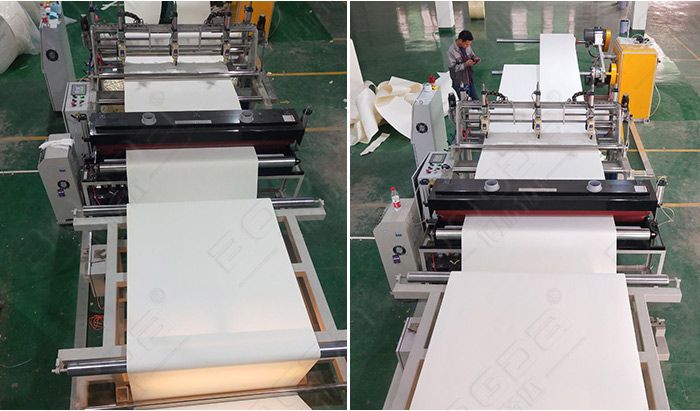

Mixing+ Extrusion Machine for SHEET

1) Pellet Mixing 2) Single Screw Extruder 3) Mould Die by hangle 4) Water Cooling Tank (USED FOR FLOORING) 5) Double-set Haul-off Pulling with side cutting 6) Sheet Winding Machine 7) Waste Sheet Crushing Machine

8) Capacity: 80-200KGS/H (depend on formula)

High Frequency and High Voltage Electron Accelerator

1- Shielding method: Both the irradiation hall and the main body of the accelerator are shielded by reinforced concrete gun towers. 2- Plant height: The plant is required to be no less than 17 meters. (The flue height is not less than 20 meters) 3- Driving requirements: 1*10T driving vehicle is required 4- Inspection method: Inspection platform and accelerator body need to be inspected maintained by opening the cover of the vehicle. 5- Features and advantages: This type of accelerator is the first-generation accelerator, and the accelerator energy can be manufactured from 0.5MeV-5.0MeV.

Foaming Furnace (Vertical for IXPE)

Capacity: 30-60KGS/H, normally 1SET Extrusion SHEET LINE can work 3-5PCS foaming furnace. So please tell us the capacity you want to make, for example, one day how many square meters?

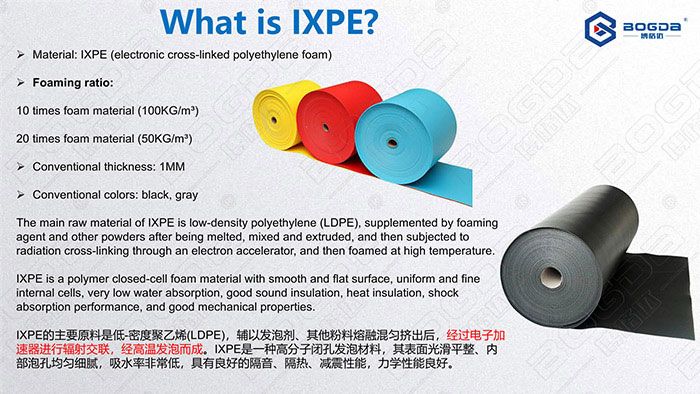

Although XPE and IXPE are both PE foam, XPE's pores are coarser, and IXPE's pores are uniform and fine with smooth surface, which is obvious through cross-section comparison.

Product Paramenters

| Extruder | SJ90 | SJ120 | SJ150 | SJ180 |

| Screw Diameter (mm) | 90 | 120 | 150 | 180 |

| L/D | 25:1 | 25:1 | 25:1 | 25:1 |

| Screw speed (r/min) | 10-38 | 10-38 | 10-38 | 10-38 |

| Foaming times | 5-35 | 5-35 | 5-35 | 5-35 |

| Cooling method | Water cooling | |||

| Capacity (kg/h) | 80 | 120 | 180 | 220 |

| Production Width (mm) | 1100 | 1100-1300 | 1100-1400 | 1100-1600 |

| Production Thickness (mm) | 2.0-6.0 | 2.0-6.0 | 3.0-12.0 | 3.0-12.0 |

| Total power (kw) | 200 | 315 | 400 | 450 |

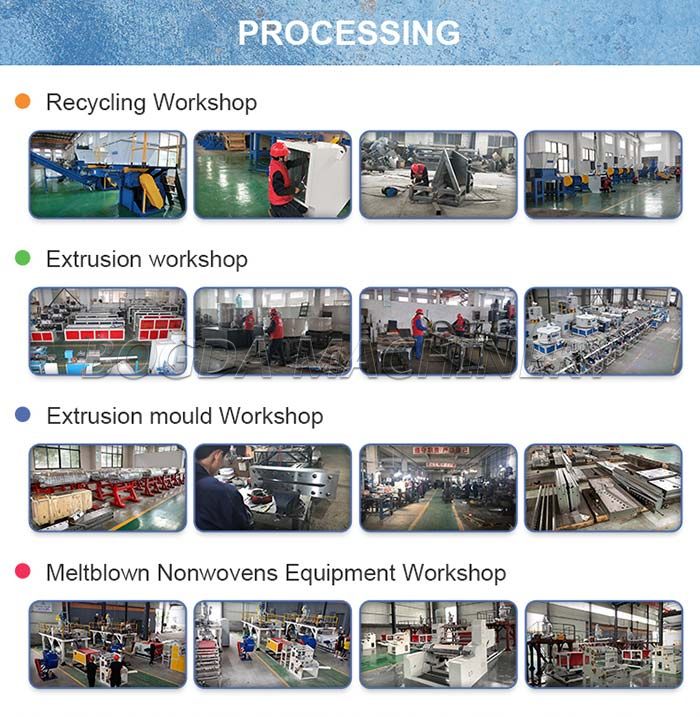

BOGDA Machinery Group is located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

Q: Where can we get spare part?

A: We choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How can I help you when face some technical problem?

A: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Q: How long is the guarantee?

A: 12 months since the first day customer operates (except wear parts).

Q: Any quality checking before shipment?

A: 100% confirm, run and test machines before shipment with quality certificate.

Q: Can I operate machine if don’t have experienced engineers?

A: (1) Short-time engineers to customer company (5-15days) (2) Year-time working as requirements

Q: How many electric, water, air need for the machines?

A: Technical department supply the whole layout for workshop details.

Copyright © Bogda Machinery Group All Rights Reserved | Sitemap